The electrification of the African continent represents one of the most critical infrastructure frontiers of the 21st century. As urbanization accelerates in cities like Lagos, Nairobi, Kinshasa, and Addis Ababa, the demand for reliable public lighting has outpaced the expansion of national power grids. For government ministries, Engineering, Procurement, and Construction (EPC) contractors, and private developers, the shift from traditional grid-tied high-pressure sodium (HPS) lighting to solar street light solutions for Africa is no longer merely an "alternative" environmentally friendly option—it is frequently the only economically and logistically viable strategy.

However, the African market is littered with failed solar projects. Flickering lights, rusted poles, and batteries that die after six months are common sights in many municipalities. These failures are rarely due to the technology itself, but rather a lack of understanding of the project lifecycle. Purchasing a solar light is a transaction; executing a solar lighting infrastructure project is a complex engineering discipline.

This 6,000-word comprehensive guide provides a definitive roadmap for navigating the unique terrain, aggressive climate, and complex procurement challenges of the African market. We will dismantle the process into seven actionable stages, moving from problem identification to long-term asset management.

Before a single purchase order is signed, the specific "pain point" must be diagnosed. In the context of rural electrification solar project Africa initiatives or urban renewal, the demand is rarely homogenous. It stems from distinct socioeconomic and infrastructural pressures.

In many rapidly expanding urban centers, darkness is a direct enabler of crime. Local municipalities often initiate lighting projects specifically to create "safe corridors." Research indicates that reliable street lighting can reduce street crime by up to 20% in urban African settings. The problem here is not just "lack of light," but "lack of reliable light." A grid-tied light that is off during a blackout is useless for security. This drives the demand for off-grid solar solutions that operate independently of the unstable national supply.

Grid instability—colloquially known as load shedding in Southern Africa or "dumsor" in West Africa—is a primary driver for solar adoption. When the grid fails, traffic signals and street lights go dark, causing chaos and accidents. Off-grid lighting projects Africa are increasingly mandated for critical intersections and highways to ensure that road safety infrastructure remains functional 24/7, regardless of the national utility's status.

For rural villages, mining sites, and new agricultural developments, the nearest substation may be 50 kilometers away. The capital expenditure (CAPEX) required for cabling, trenching, and transformers to extend the grid to these locations is often prohibitive. In these scenarios, the problem is purely economic: How do we provide light without the massive civil engineering cost of grid extension? Solar eliminates the "last mile" infrastructure requirement entirely.

Understanding the problem also requires understanding how African procurement officers and contractors search for solutions. They rarely search for generic terms like "LED light." Their search intent is problem-focused.

Common Research Queries:

Once the need is identified, the project moves to feasibility. This is the stage where most failures are seeded. A solar light designed for the mild climate of Northern Europe will inevitably fail in the Sahel or the tropical belt of Central Africa. A rigorous environmental assessment is non-negotiable.

Africa is blessed with some of the highest solar irradiance levels on the planet, typically ranging from 4.5 to 6.5 kWh/m²/day. However, this abundance varies significantly by region and season.

Heat: Ambient temperatures in many African nations can exceed 45°C. Inside a black metal housing, the internal temperature can reach 70°C. Standard Lead-Acid or Gel batteries degrade rapidly above 45°C. Feasibility studies must mandate the use of high-temperature tolerant Lithium Iron Phosphate (LiFePO4) batteries.

Dust (The Harmattan Factor): In West Africa, the Harmattan season brings fine dust that coats solar panels, reducing efficiency by up to 40%. Feasibility designs must account for this by oversizing the solar panel by 30-50% or increasing the installation angle to allow rain to self-clean the panels.

Corrosion: Coastal cities like Lagos, Accra, Mombasa, and Dar es Salaam have high salinity in the air. Standard aluminum alloys will oxidize and crumble within 2 years. Marine-grade powder coating and stainless steel fasteners are essential requirements.

Feasibility often hinges on the budget. While solar has a higher upfront Capital Expenditure (CAPEX), its Operational Expenditure (OPEX) is near zero. The following table is a crucial tool for developers to justify the budget allocation to finance ministries.

| Cost Driver | Grid-Tied Street Lighting | Solar Street Lighting |

|---|---|---|

| Infrastructure (CAPEX) | High: Cabling, trenching, transformers, switchgear, distribution panels. | Medium: Self-contained units. No external wiring or substations needed. |

| Energy Consumption (OPEX) | High: Monthly electricity bills, subject to tariff hikes and inflation. | Zero: Free energy from the sun. |

| Maintenance (OPEX) | Medium: Bulb replacement, cable repairs (theft/damage), transformer servicing. | Low/Medium: Battery replacement (every 5-7 years), periodic panel cleaning. |

| Risk Factors | Cable theft (high resale value of copper); Blackouts disable the system. | Panel/Battery theft (mitigated by anti-theft design); Immune to blackouts. |

| Installation Time | Slow: Requires major civil works and coordination with utility companies. | Fast: "Plug and Play" installation. 100+ units can be installed per week. |

This is the engineering core of the project. To ensure longevity, the specifications must be tailored to the specific application. A "one-size-fits-all" approach is the leading cause of project failure in Africa.

In solar lighting, every watt of power consumed must be generated and stored. Therefore, LED efficiency is paramount.

Recommendation: Use high-efficacy LED chips (e.g., Philips, Cree, or Bridgelux) that deliver 160-180 lumens per watt. A cheap LED chip might only deliver 100 lumens per watt, meaning you need nearly double the battery power to achieve the same brightness.

For the best solar street lights for African climate, Lithium Iron Phosphate (LiFePO4) is the industry standard.

We highly recommend MPPT solar controllers (Maximum Power Point Tracking) over PWM (Pulse Width Modulation).

Why MPPT? An MPPT controller adjusts the voltage and current in real-time to extract the maximum power from the solar panel, regardless of temperature or sunlight intensity. In the African context, this offers a 20-30% increase in charging efficiency, which is critical during the rainy season to prevent blackouts.

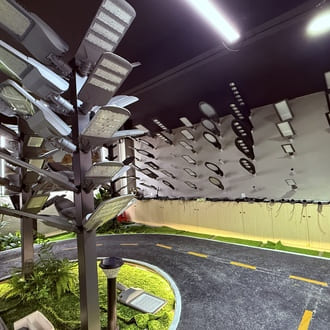

The market is divided between these two designs. Explore our full range of Solar Street Light configurations here.

Design: The solar panel, battery, controller, and LED are integrated into a single body.

Pros: Extremely easy to install (5 minutes/unit); sleek aesthetic; harder to steal individual parts.

Cons: Fixed panel angle (cannot be adjusted to face the sun optimally); limited battery capacity due to size constraints.

Best For: Village roads, courtyards, community centers, areas near the equator.

Design: The solar panel is mounted separately on top of the pole, and the LED head is on an arm.

Pros: Panel can be rotated to the perfect angle for maximum sun exposure; supports much larger panels and batteries for high-power applications (80W-150W).

Cons: More complex installation; requires stronger poles to support wind load.

Best For: Major highways, roundabouts, security perimeters.

Use this table as a baseline for drafting tender specifications.

| Application | Pole Height | LED Wattage | Panel Wattage | Battery Capacity (LiFePO4) | Autonomy (Rainy Days) |

|---|---|---|---|---|---|

| Rural Path / Village | 5 - 6 Meters | 30W - 40W | 60W - 80W | 30Ah - 40Ah (12.8V) | 2 - 3 Days |

| Urban Connector Road | 7 - 8 Meters | 60W - 80W | 120W - 150W | 60Ah - 80Ah (12.8V) | 3 Days |

| Highway / Main Artery | 10 - 12 Meters | 100W - 120W | 200W - 300W | 100Ah - 150Ah (12.8V) | 4 - 5 Days |

| Mining / Industrial | 9 Meters | 100W (High Lumen) | 200W | 100Ah (12.8V) | 3 Days + Motion Sensor |

Sourcing from a solar street light supplier China requires extreme vigilance. The market is flooded with sub-standard products where a label says "200W" but the actual output is barely 50W. This section empowers African buyers to identify quality.

In the low-end market, wattage is a marketing term, not a technical spec. A "300W" solar light sold on a marketplace for $30 is physically impossible.

How to Verify:

The battery is the most expensive component. Unscrupulous suppliers may use recycled electric vehicle batteries or label a 20Ah battery as 100Ah.

The Buyer's Question: "Please provide the battery pack dimensions and net weight."

The Logic: Lithium density is constant. A 12.8V 100Ah LiFePO4 battery pack will weigh approximately 10-11kg. If the supplier says it weighs 3kg, it is fake.

Importing into African nations often requires specific Conformity Assessment Programs to clear customs. Ensure your manufacturer is experienced with these processes:

.jpg)

For government tenders requiring verifiable specs and high durability, we recommend the RC-Light-ST. This model is engineered with a die-cast aluminum housing specifically for heat dissipation in tropical climates and features an easy-access battery compartment for future maintenance. View the technical specifications of the RC-Light-ST here.

Once manufacturing is complete, the logistics phase begins. This is often where delays occur if not managed by an experienced team. The distance between a Chinese factory and a site in rural Zambia is vast, involving multimodal transport.

Efficient packing saves thousands of dollars in freight.

Poles: Should be designed in sections (e.g., a 8m pole split into two 4m sections) to fit inside a standard 40ft container.

Batteries: Classified as Dangerous Goods (UN3480). They require special packaging labeling and cannot be shipped on passenger aircraft.

Improper installation is a leading cause of early failure. Orientation is critical.

The project does not end at installation. Long-term success is measured by reliability and Total Cost of Ownership (TCO).

Solar lights are "low maintenance," not "no maintenance."

| Symptom | Probable Cause | Solution |

|---|---|---|

| Light works for 2 hours then dies. | Old battery or insufficient charging (dirty panel/shade). | Clean panel; Check for shadows; Replace battery if >5 years old. |

| Light does not turn on at night. | Panel or Battery disconnected; LED failure. | Check wiring voltage. If panel voltage is 0V in sun, panel is damaged. |

| Light stays on during the day. | Panel is not detecting sunlight (covered or faulty). | Clean the panel. Ensure no artificial light (like a billboard) is shining on the panel at night. |

For large-scale highway projects, we recommend integrating IoT (Internet of Things) modules using Zigbee or GPRS/4G. This allows the central control room to:

Africa renewable energy solutions are scaling up. We are seeing distinct patterns in successful deployments across the continent that serve as models for future projects.

Scenario: A rural community in West Africa with no grid access.

Solution: Deployment of 300 units of 40W All-in-One Solar Street Lights.

Impact: Small businesses (kiosks) extended operating hours from 6 PM to 10 PM. Children could study outside under the street lights. Community gatherings increased.

Key Takeaway: For community projects, simplicity (All-in-One) reduces installation errors and maintenance burden.

Scenario: A copper mine in Central Africa requiring 24/7 security lighting.

Solution: 120W Split-Type lights with oversized batteries (5 days autonomy) and motion sensors.

Impact: Reduced fuel theft and perimeter breaches. The lights maintain a low dim level and blast to 100% brightness when motion is detected, alerting guards.

Key Takeaway: Industrial projects prioritize autonomy and reliability over aesthetics.

Scenario: An existing highway with non-functional grid lights due to cable theft.

Solution: Retrofitting existing poles with Solar Heads.

Impact: Saved 60% on infrastructure costs by reusing existing poles. Restored safety to a high-accident zone.

Key Takeaway: Retrofitting is a viable, cost-effective strategy for cash-strapped municipalities.

At Henan Ruichen Traffic Equipment Co., Ltd, we do not just sell lights; we engineer project outcomes. We understand that a light installed in a coastal city requires different specifications than one installed in a desert mine.

Our Capabilities Include:

Are you ready to illuminate your next project with reliable, high-performance solar solutions?