Hot sale led solar studs cost

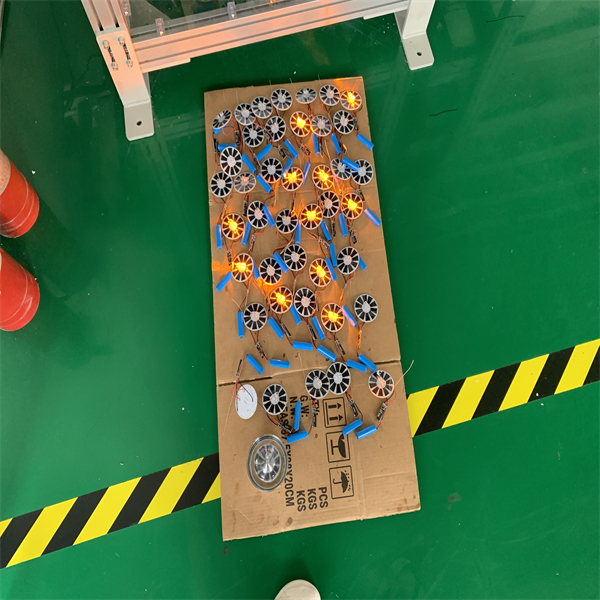

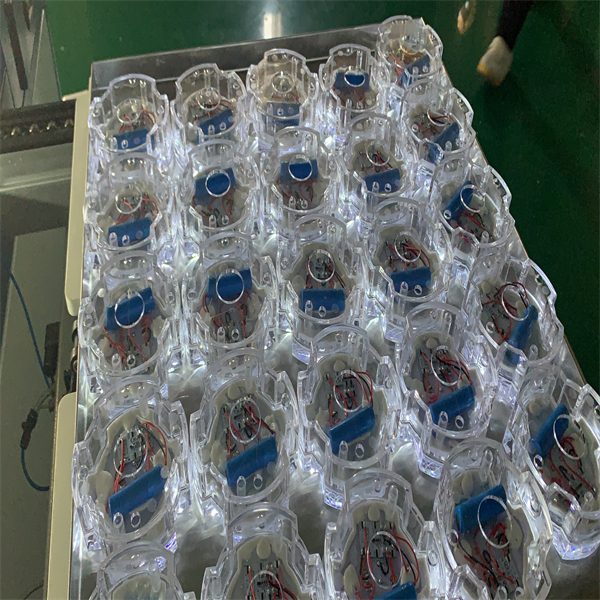

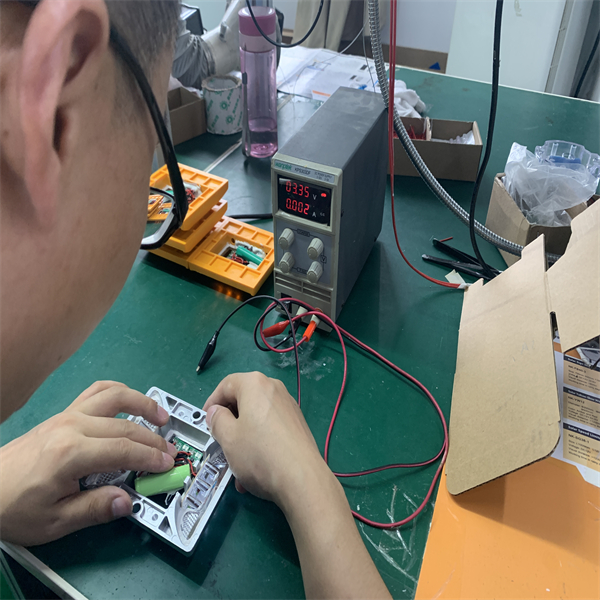

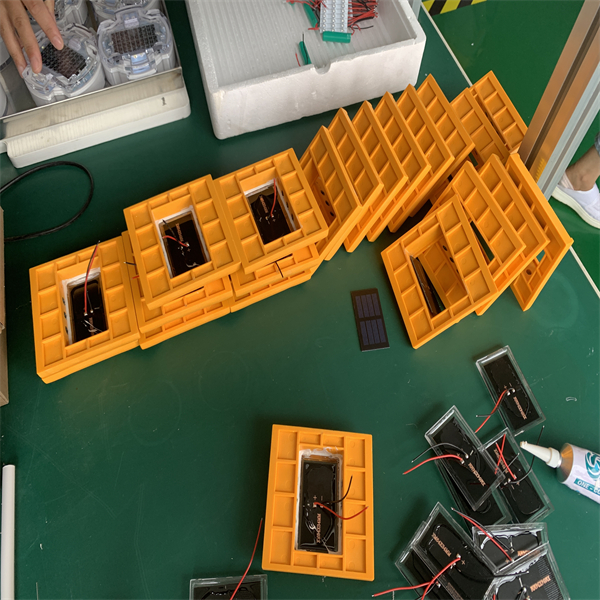

The main PE trunk line used by Solar Studs is cable metal sheath, which has a difficult manufacturing process and low reliability. The PE trunk line cable’s metal wrapping is made using a laborious fabrication technique. Two solder points, each of which must be stripped, polished, tinned, and soldered, must be soldered onto each base Solar Stud. The process is time-consuming, and it is challenging to ensure the integrity of the solder junctions. The reliability of the PE main line connection can be envisaged when more solder joints are linked in series.

The main PE trunk line used by Solar Studs is cable metal sheath, which has a difficult manufacturing process and low reliability. The PE trunk line cable’s metal wrapping is made using a laborious fabrication technique. Two solder points, each of which must be stripped, polished, tinned, and soldered, must be soldered onto each base Solar Stud. The process is time-consuming, and it is challenging to ensure the integrity of the solder junctions. The reliability of the PE main line connection can be envisaged when more solder joints are linked in series.

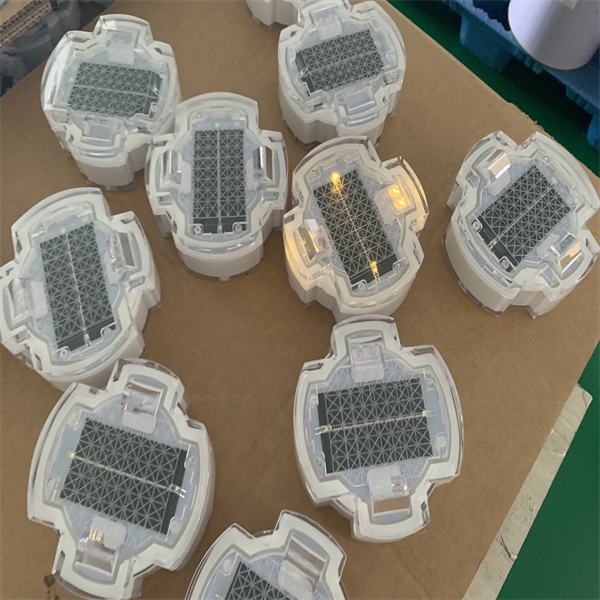

Additionally, total moisture resistance for Solar Studs cables is all but impossible. Rust and corrosion of the metal sheath are unavoidable as long as moisture builds up inside the cable. The protective effect of the PE main line usually wears off after three to five years, leaving the metal skin of the Solar Studs low-voltage cable looking rusty at the breakpoints. In this manner, once a single-phase ground fault happens, harmful voltage will persist for a considerable amount of time even though the ground protection of each Solar Stud is actually “independent”.