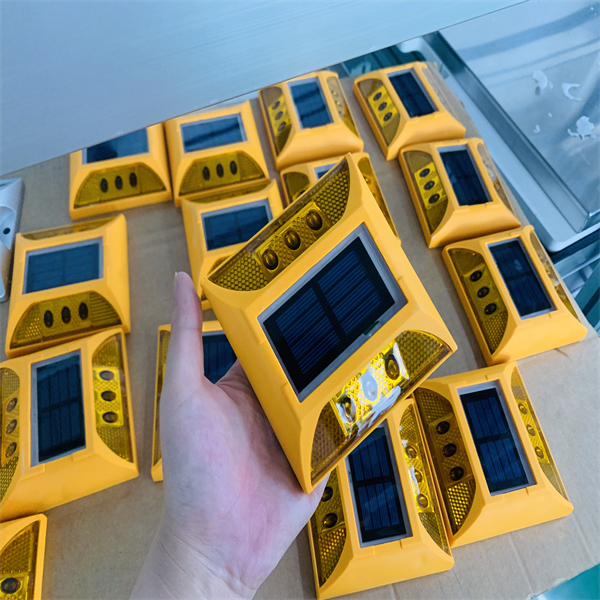

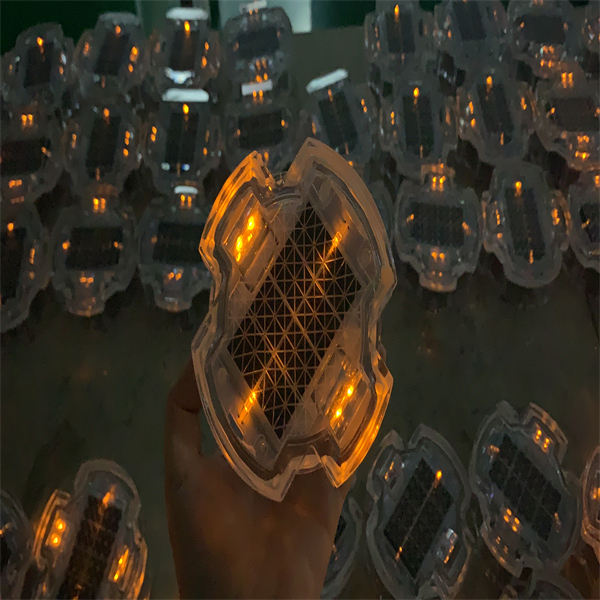

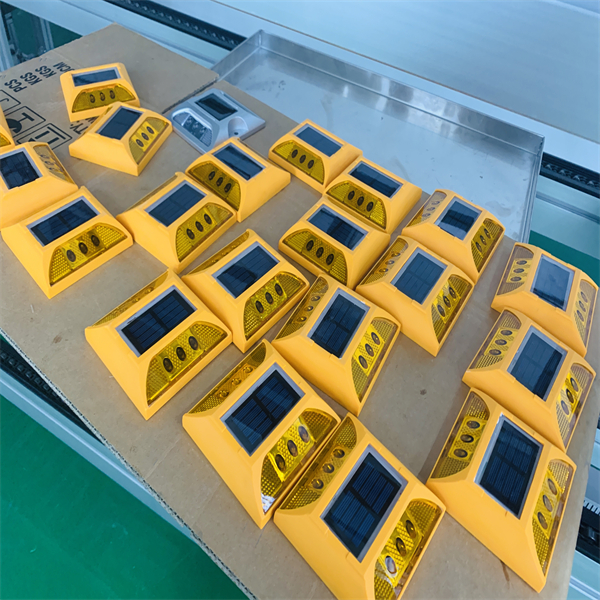

What is the most correct installation procedure for Reflective Studs?

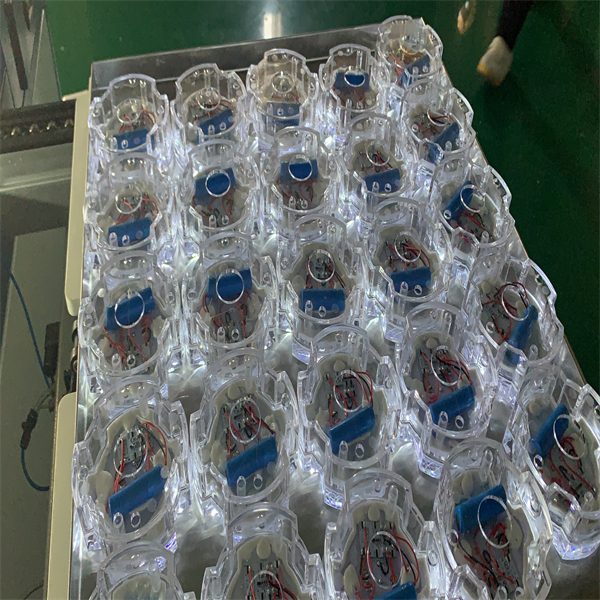

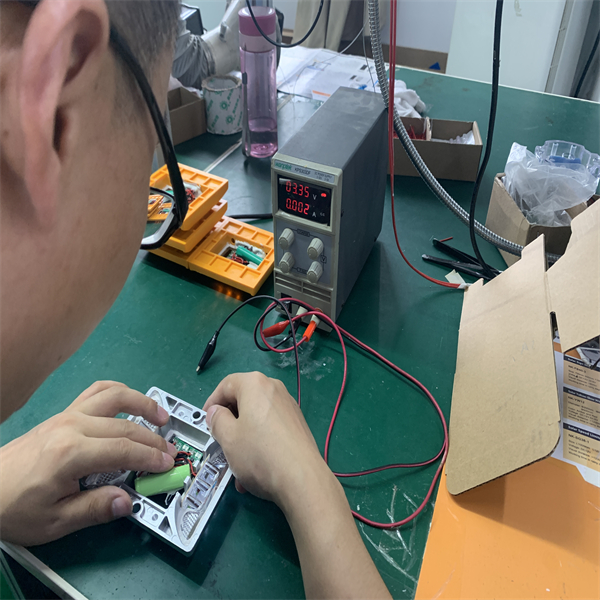

RuiChen Reflective Studs are composed of A and B components. Mechanical stirring should be used for the preparation. The stirrer can be composed of electric hammer and stirring teeth. The stirring teeth can be made of cross-shaped Φ steel bars welded to the end of the electric hammer bit. Small amounts (means less than 0.5 kg) can also be manually stirred with Φ6 and Φ8 thin steel rods. (Note: Only use a knives for mixing, it cannot be guaranteed to be evenly mixed). Take a clean container (plastic or metal basin, free of oil, water, impurities) and weighing scale to mix according to the proportion, and stir with a stirrer for about 10 minutes until the A and B components are evenly mixed. It is best to stir in the same direction when stirring, and try to avoid mixing air to form bubbles. The amount of glue should not be too much each time, and use it now. The main equipment used: agitator, container, weighing apparatus, knives, gloves.

Adhesive surface treatment→preparation of structural adhesive→gluing and pasting→curing and maintenance

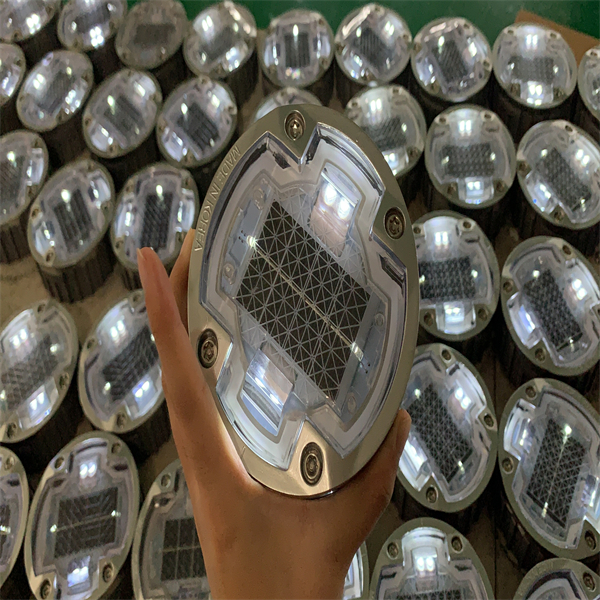

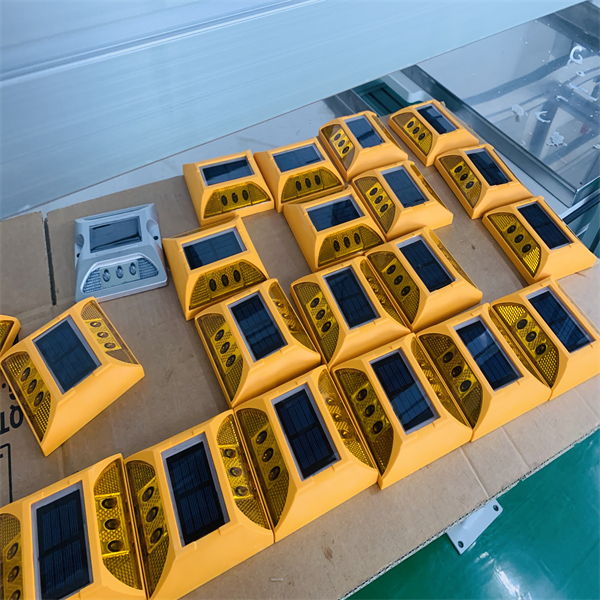

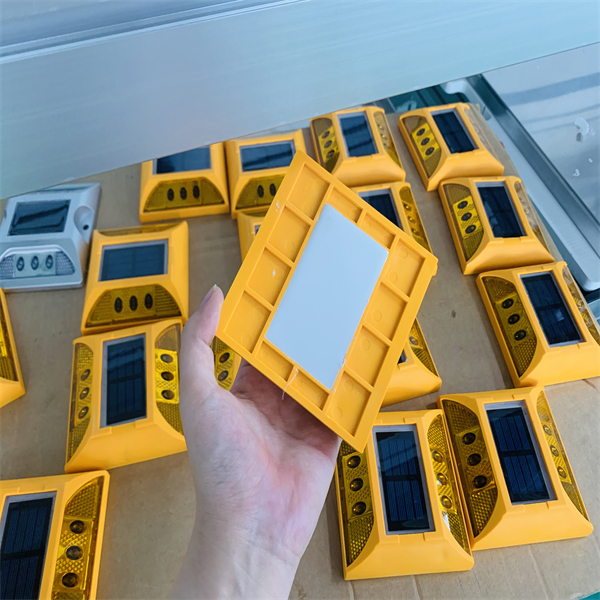

- Adhesive surface treatment of Reflective Studs:

Use an angle grinder to polish the pavement paste to remove the 1-2mm thick surface layer to a solid base, wipe the surface with a cotton cloth dipped in acetone, and keep it dry. Chang’an road stud glue can be used to repair large depressions to smooth the road studs and avoid expansion joints on the road.

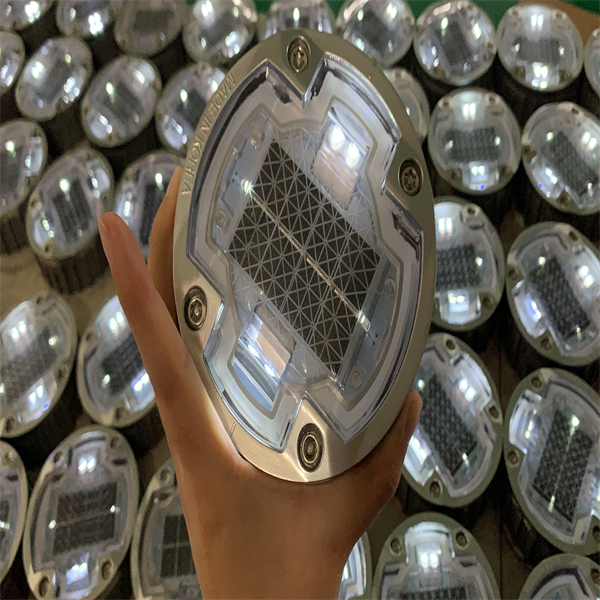

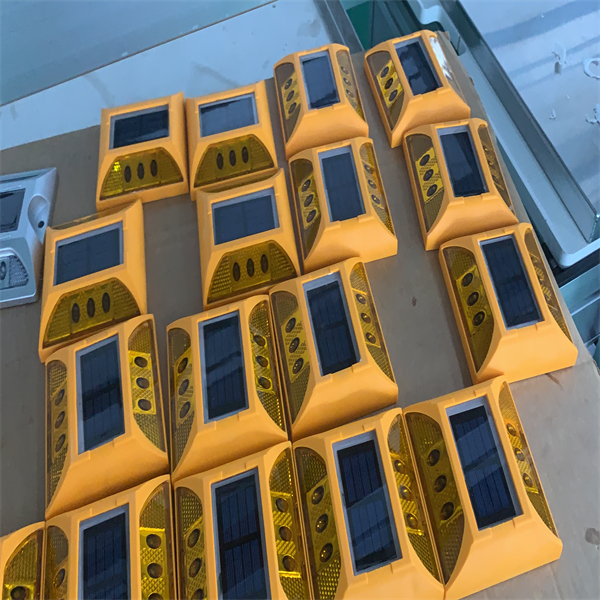

The adhesive surface of Reflective Studs should also be clean and dry. The main equipment used: angle grinder, grinding disc, cotton cloth, dust mask.

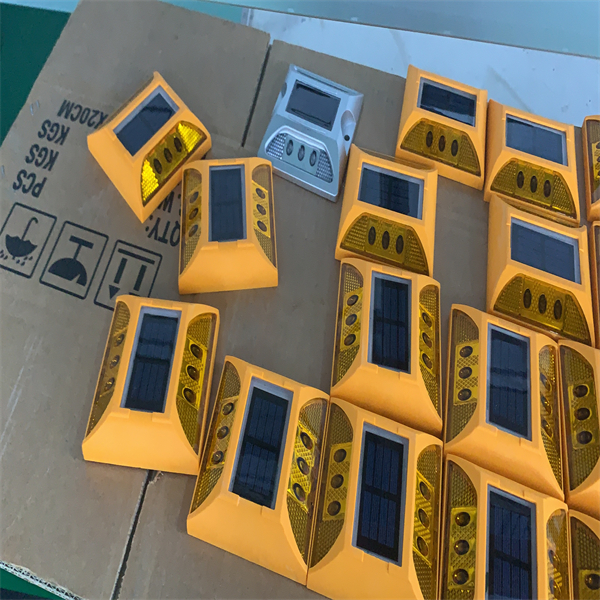

- Reflective Studs compound glue:

RuiChen Reflective Studs are composed of A and B components. Mechanical stirring should be used for the preparation. The stirrer can be composed of electric hammer and stirring teeth. The stirring teeth can be made of cross-shaped Φ steel bars welded to the end of the electric hammer bit. Small amounts (means less than 0.5 kg) can also be manually stirred with Φ6 and Φ8 thin steel rods. (Note: Only use a knives for mixing, it cannot be guaranteed to be evenly mixed). Take a clean container (plastic or metal basin, free of oil, water, impurities) and weighing scale to mix according to the proportion, and stir with a stirrer for about 10 minutes until the A and B components are evenly mixed. It is best to stir in the same direction when stirring, and try to avoid mixing air to form bubbles. The amount of glue should not be too much each time, and use it now. The main equipment used: agitator, container, weighing apparatus, knives, gloves.

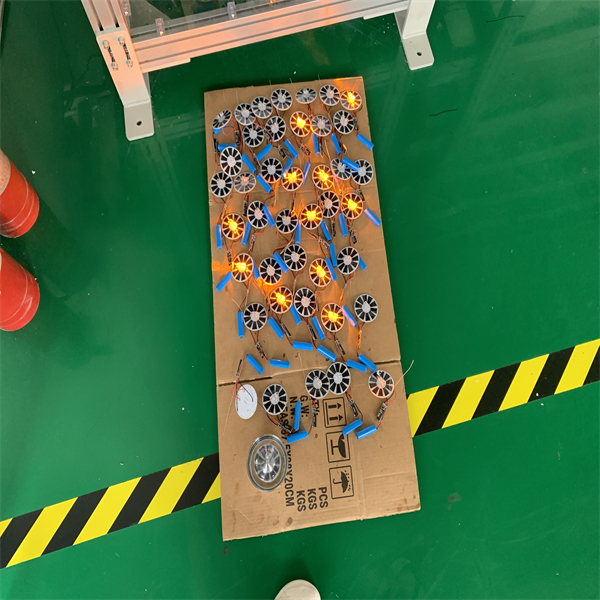

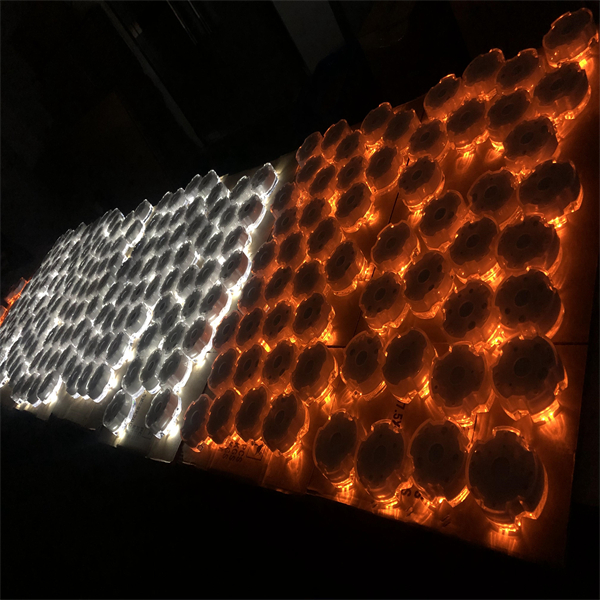

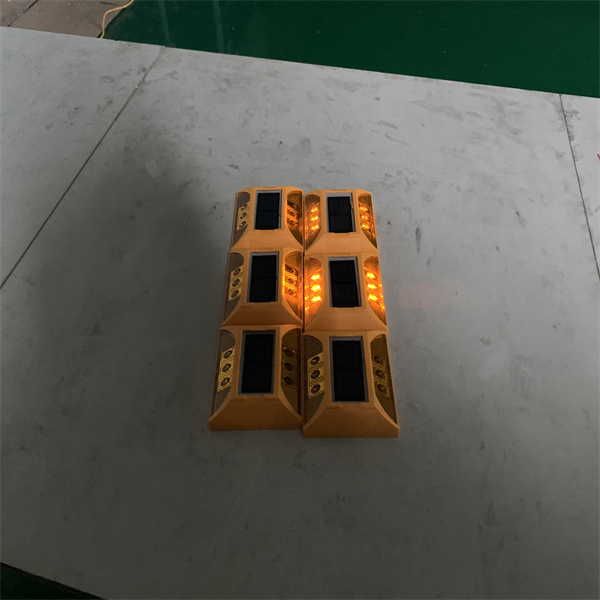

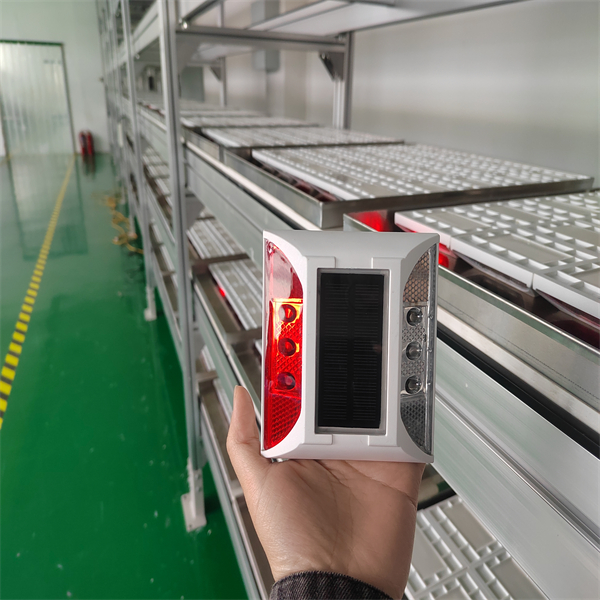

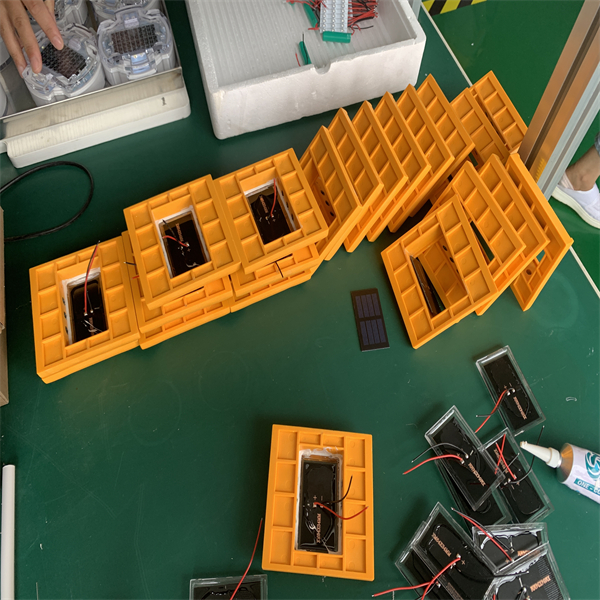

- Reflective Studs gluing and pasting:

After the adhesive is prepared, apply it evenly on the pavement or Reflective Studs sticking surface with a grease knife. The thickness of the adhesive is about 2 mm. Align the position and apply slight pressure with your fingers. It is advisable to just squeeze the glue from the periphery of the Reflective Studs. For Reflective Studs with spikes, the hole diameter of the hole should be 4mm larger than the diameter of the spike, and the depth should be 5mm longer than the length of the spike. The dust in the hole should be blown off with compressed air, and then the mixed glue should be plugged and rammed into the hole. That’s it. The main equipment used: electric hammer, greasy knife, gloves.

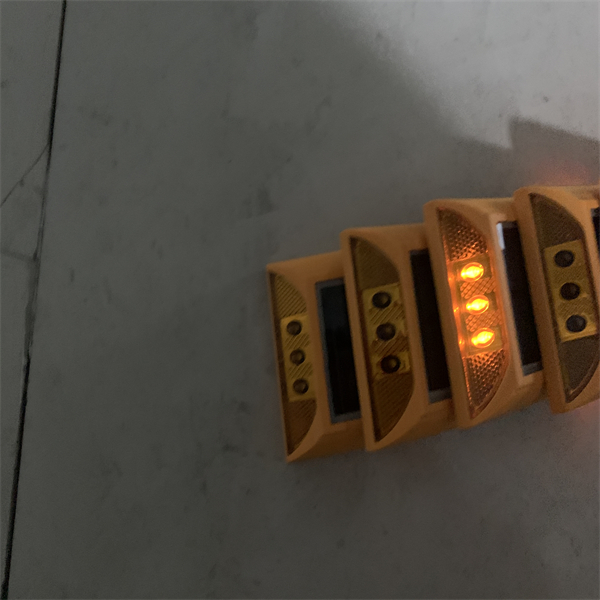

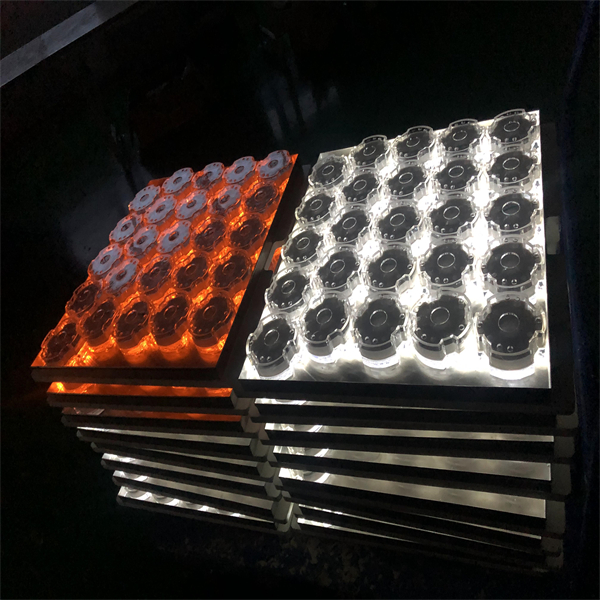

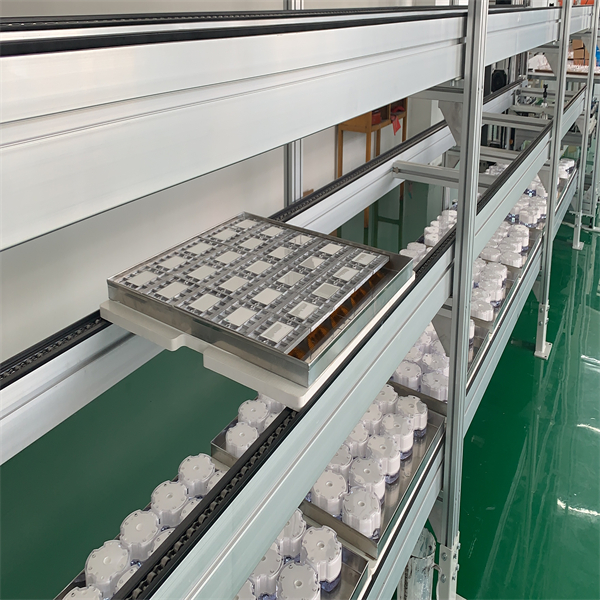

- Curing and maintenance:

RuiChen Reflective Studs can be cured well at room temperature and low temperature. If the curing temperature is about 25℃, it can be put into use in 16 hours; if the curing temperature is about 5℃, it can be put into use in 24 hours, and the bonding and anchoring force will continue with time. increase. Reflective Studs should not be disturbed within 6 hours after sticking and fixing. If there is a big disturbance, it should be re-pasted.