Do you know how to choose Reflective Studs correctly?

Reflective Studs damage is mainly caused by insufficient strength of the materials used in Reflective Studs. Reflective Studs will be subjected to static pressure load and impact load during actual use. The static pressure load is mainly formed by the tires pressing on the Reflective Studs when the vehicle is stationary; the impact load is mainly generated when the tires run over the Reflective Studs while the vehicle is running.

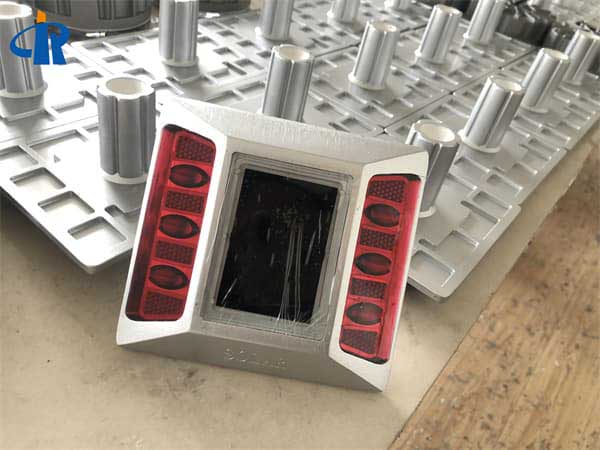

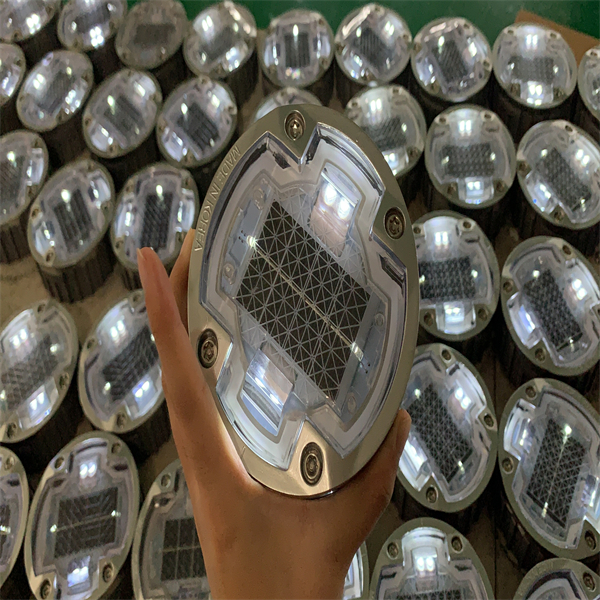

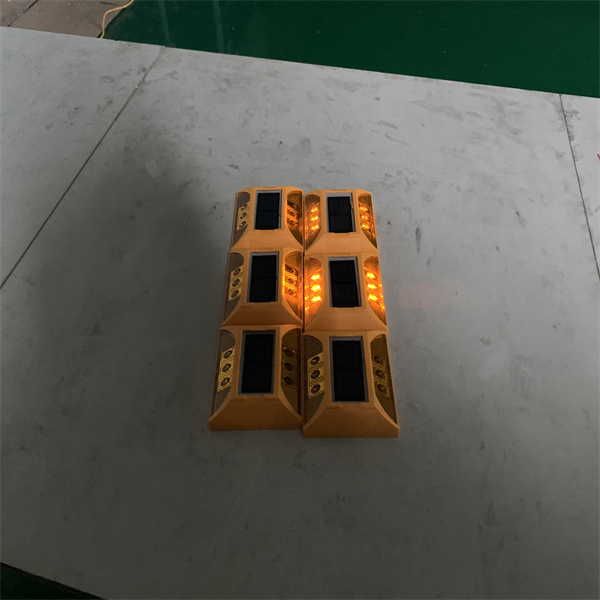

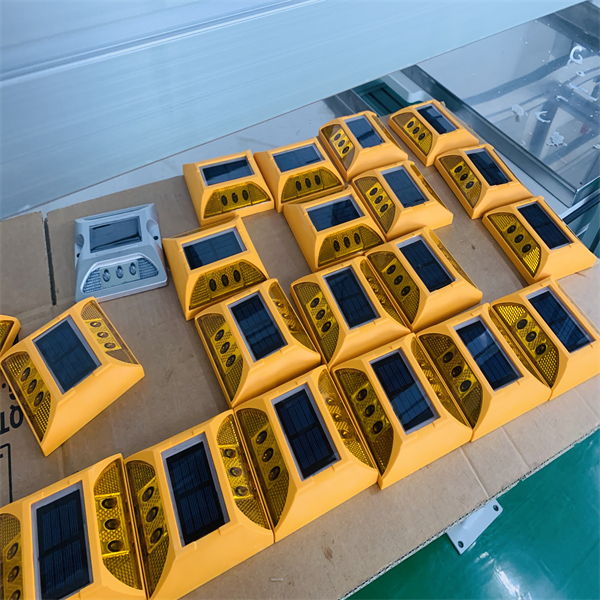

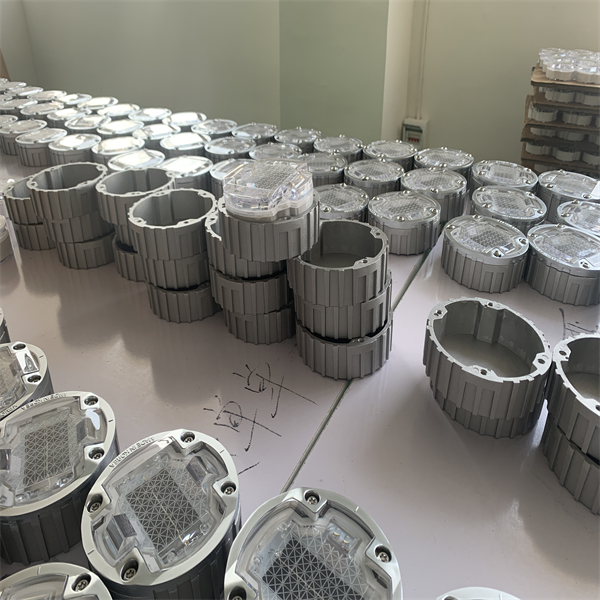

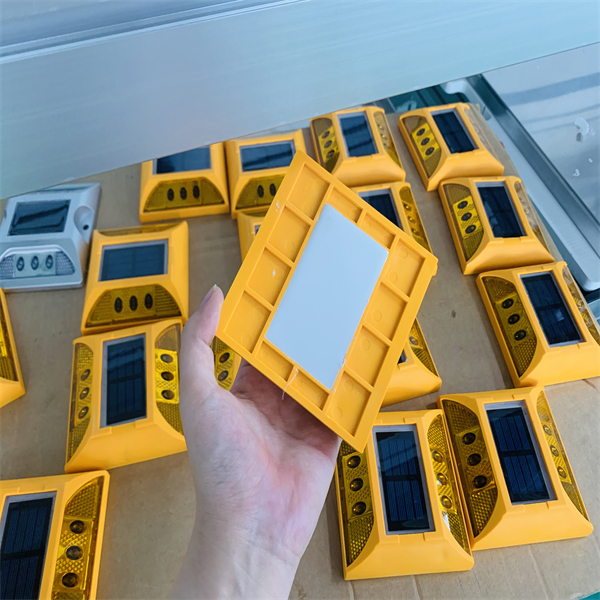

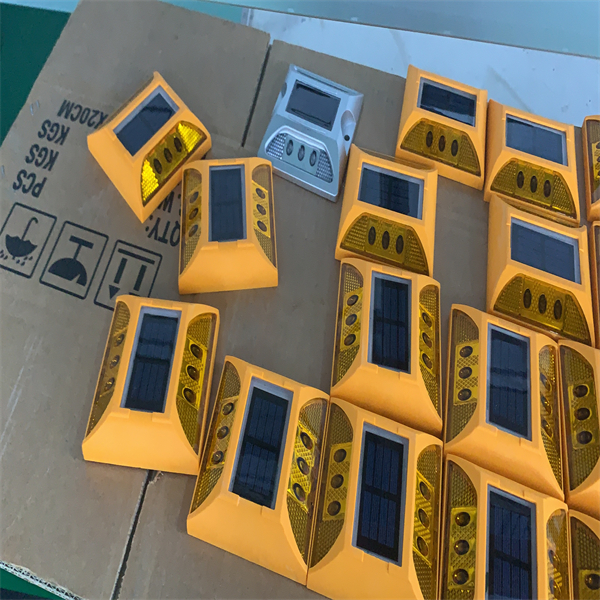

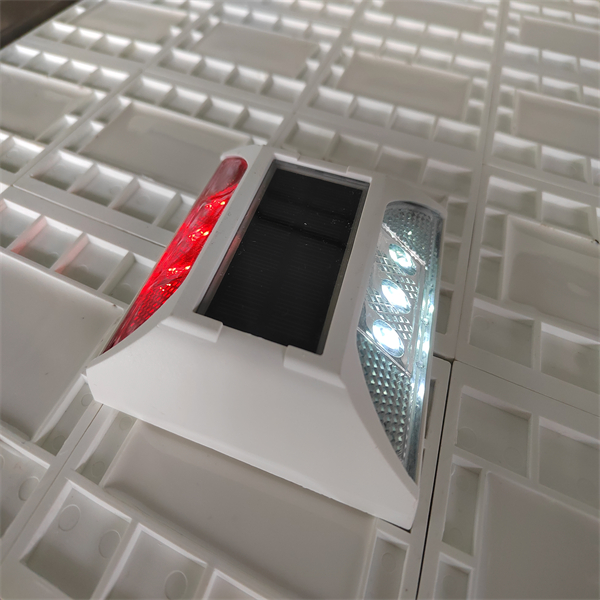

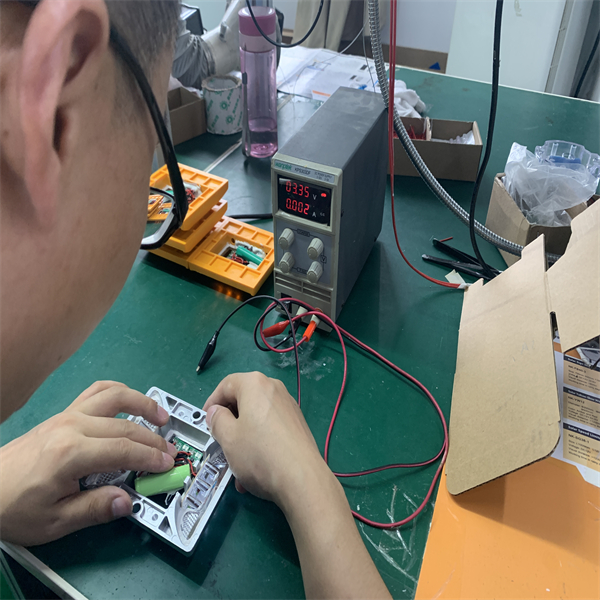

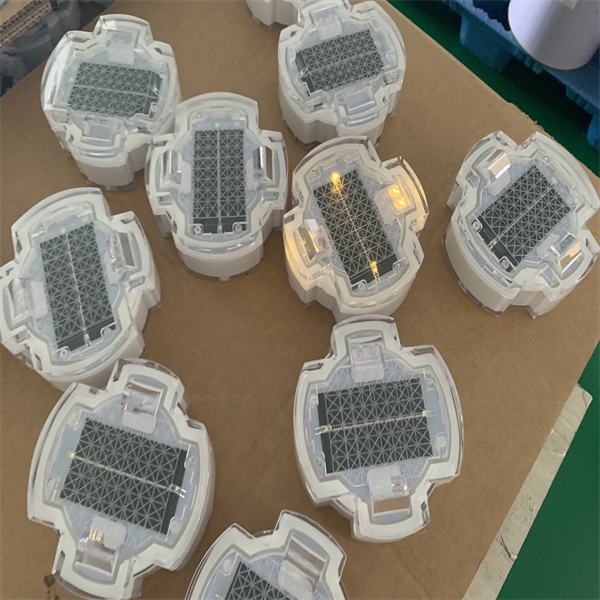

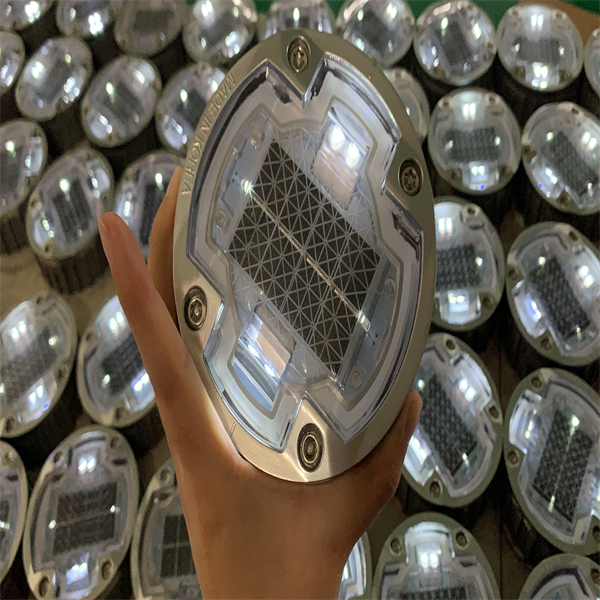

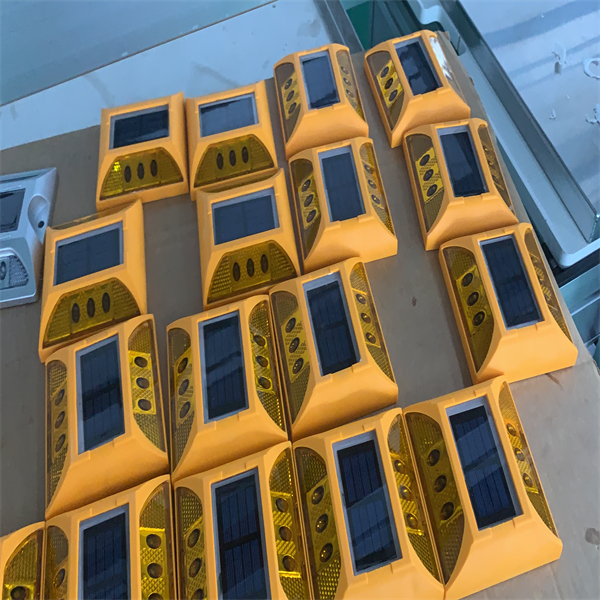

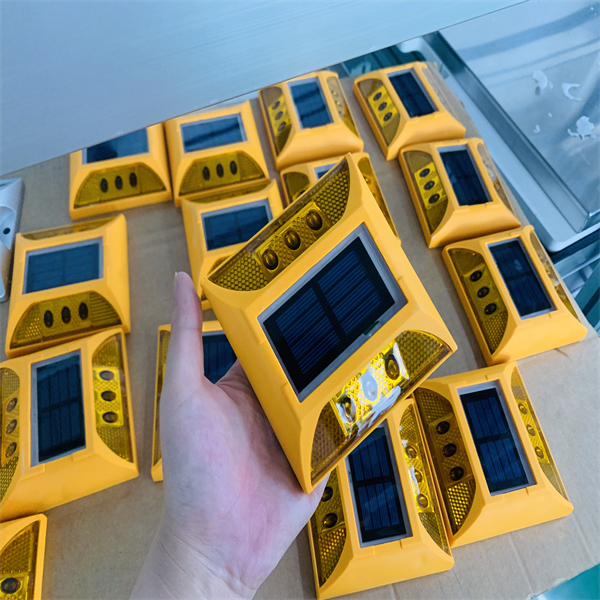

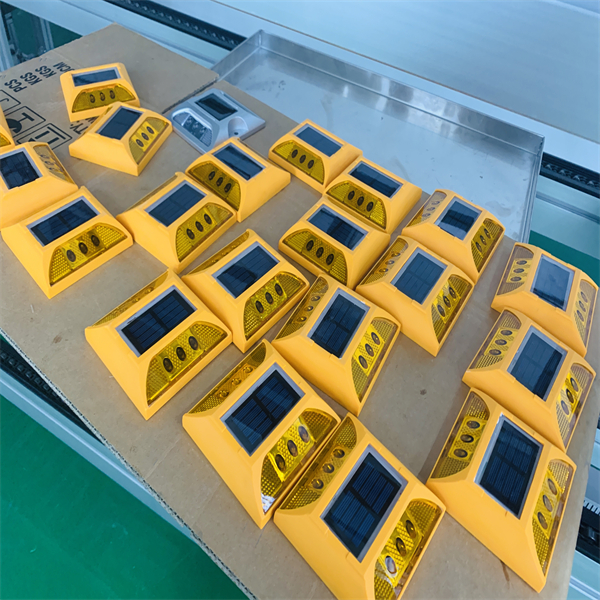

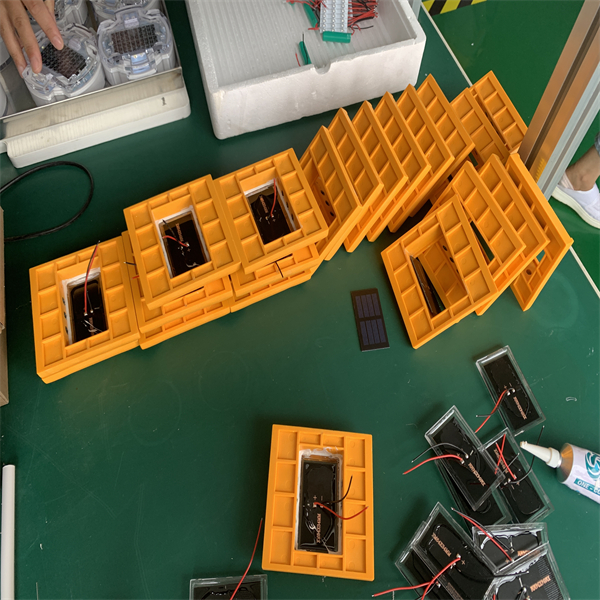

Improving the static compressive strength of Reflective Studs is mainly achieved by increasing the strength of Reflective Studs. At present, the Reflective Studs sold on the domestic market are divided into metal Reflective Studs (such as aluminum stud body Reflective Studs) and engineering plastic Reflective Studs (such as polycarbonate, polyacrylic acid and other materials). ) And mixed material Reflective Studs (such as road studs with engineering plastic shell + quartz sand filling). Among them, Reflective Studs made of metal have the highest compressive strength, followed by Reflective Studs made of engineering plastics and mixed materials.

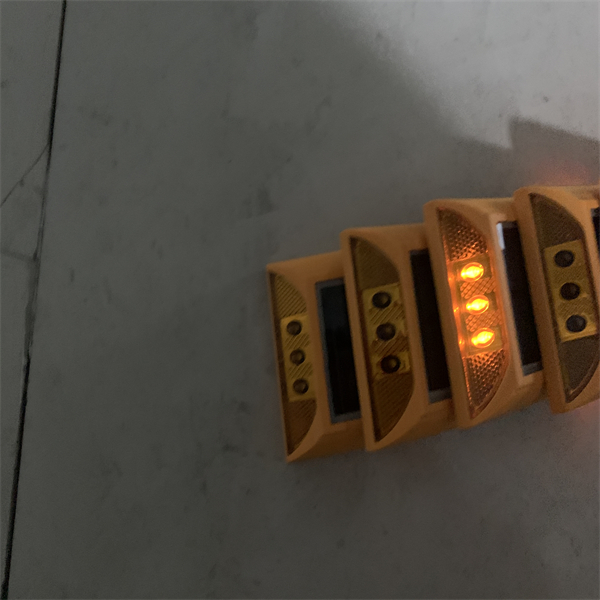

Reflective Studs are also called Reflective Studs, which are raised blocks that are fixed on the road surface and serve as markings. Together with the markings, it serves the role of marking the linear contour of the road. Especially when there is water on the road, it can replace the marking to identify the linear contour. In recent years, with the rapid development of highway construction and increasing attention to road traffic safety, the use of reflective studs has become more and more common. This article discusses how to choose Reflective Studs based on how reflective studs fail and its causes.

The failure mode and cause of Reflective Studs

Reflective Studs failure mode and cause

Reflective Studs damage is mainly caused by insufficient strength of the materials used in Reflective Studs. Reflective Studs will be subjected to static pressure load and impact load during actual use. The static pressure load is mainly formed by the tires pressing on the Reflective Studs when the vehicle is stationary; the impact load is mainly generated when the tires run over the Reflective Studs while the vehicle is running.

Improving the static compressive strength of Reflective Studs is mainly achieved by increasing the strength of Reflective Studs. At present, the Reflective Studs sold on the domestic market are divided into metal Reflective Studs (such as aluminum stud body Reflective Studs) and engineering plastic Reflective Studs (such as polycarbonate, polyacrylic acid and other materials). ) And mixed material Reflective Studs (such as road studs with engineering plastic shell + quartz sand filling). Among them, Reflective Studs made of metal have the highest compressive strength, followed by Reflective Studs made of engineering plastics and mixed materials.

Improving the impact strength of Road Studs can also be achieved by increasing the strength of Road Studs materials. In terms of materials, metal materials have the highest impact strength, followed by engineering plastic materials, and mixed materials have the lowest impact strength (due to different deformation coefficients of different materials).

Road Studs and the ground rubber,The reason for the failure of the road surface is that the lateral shear force parallel to the road surface generated when the wheel runs over the Road Studs is greater than the binding force of the Road Studs and the road surface. Therefore, it is particularly important to choose different types of primers for different pavements. For asphalt pavements, asphalt glue has the best bonding effect, and for cement pavements, epoxy resin has the best bonding effect. In addition, by optimizing the shape of the Road Studs, the effect of reducing the transverse shear force acting on the spikes or strengthening the bonding strength of the Road Studs and the road surface can be achieved. For example, road studs with feet (the feet of the stud are inserted into the ground vertically during installation) can improve the bonding strength of the road stud and the road; reduce the angle between the reflective surface of the road stud and the bottom surface of the Road Studs (that is, the reflective surface of the road stud and the road surface), It can reduce the lateral shearing force of Road Studs. It can be seen from the force analysis of Road Studs that the smaller the angle, the smaller the lateral shear force that the Road Studs body bears, and the greater the vertical pressure. The failure mode and cause of Road Studs reflector. Road Studs reflector is also called road stud. The damage effect of the road stud is mostly due to the partial or overall rupture of the reflector due to the foreign matter (such as small stones, etc.) entrained in the tire when the vehicle runs over the road stud. Road Studs’ reflectors are mostly prism-type reflectors made on the principle of total reflection. This type of reflector is characterized by high retroreflective efficiency. If the sealing structure of the reflector is damaged, once water and dust penetrate into it, its reflective efficiency will drop sharply. , Causing the reflector to not reflect light.

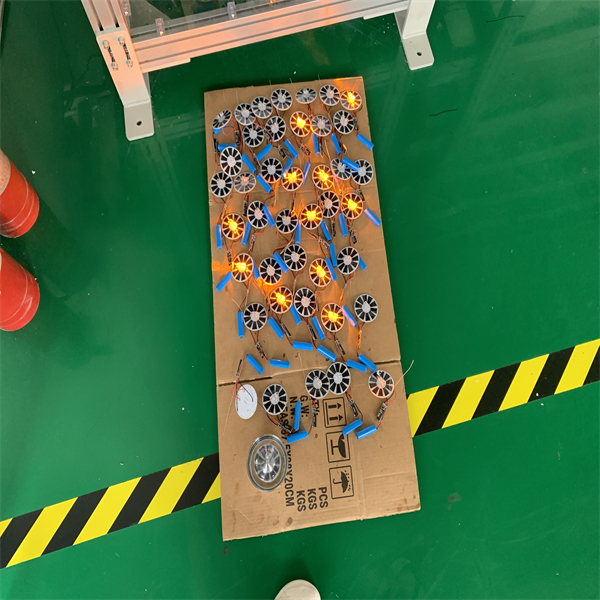

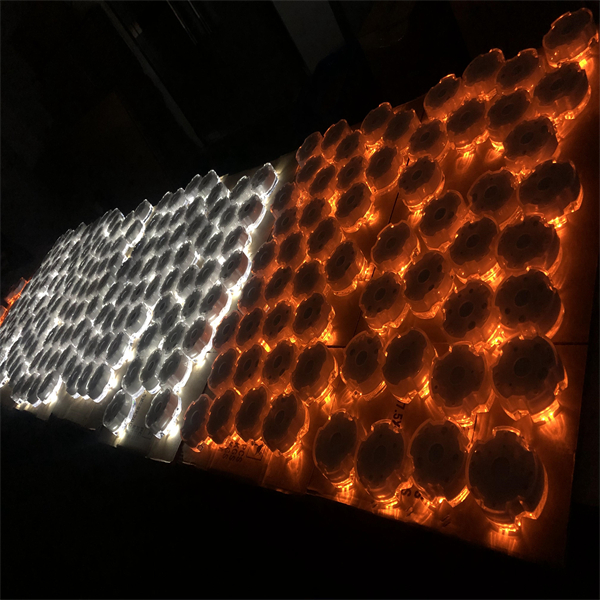

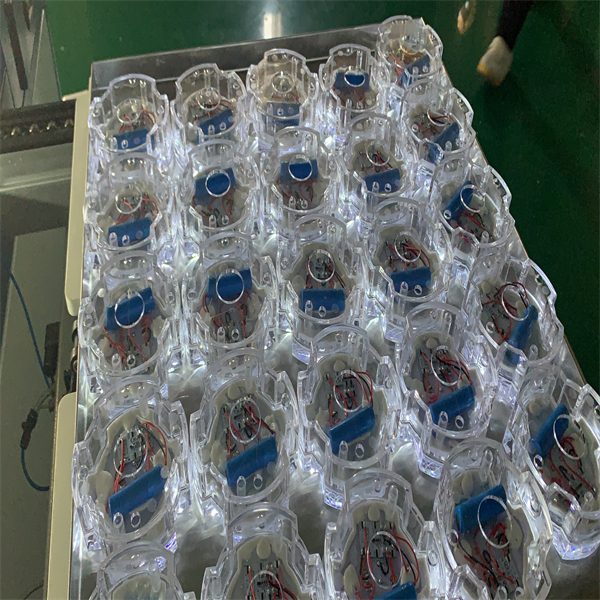

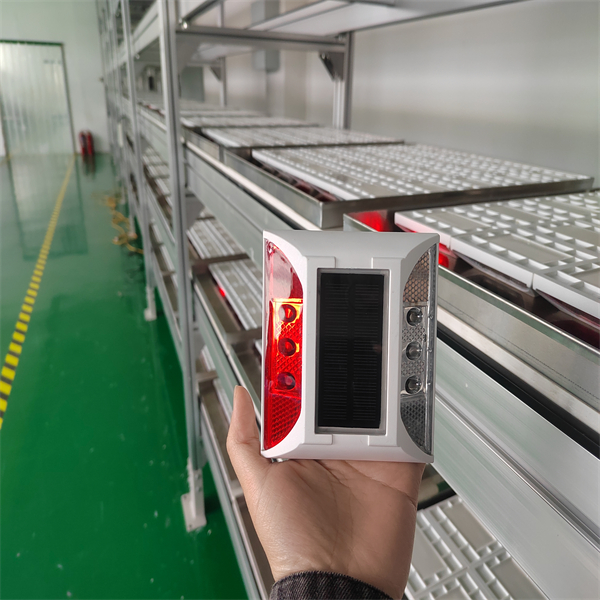

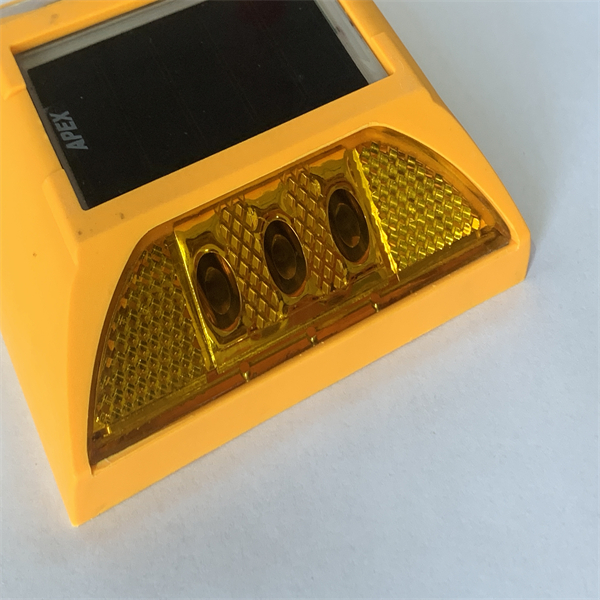

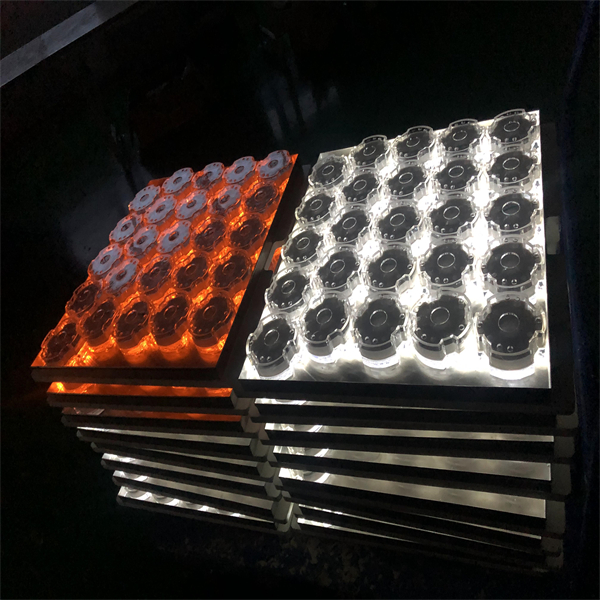

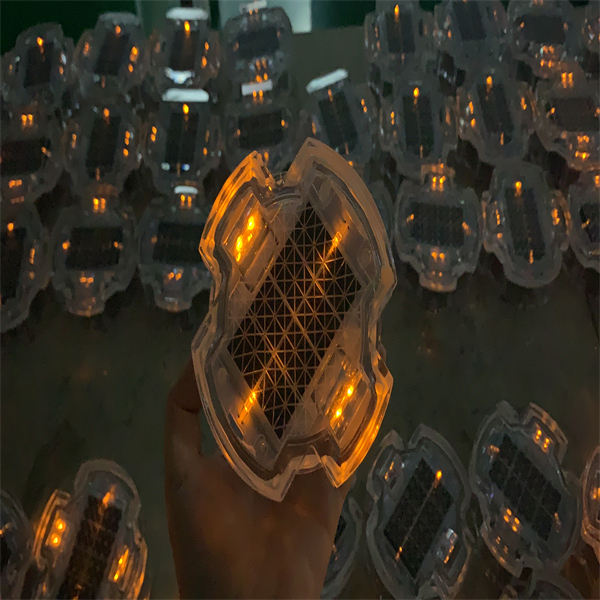

The effect of avoiding the damage of the reflective sheet can be achieved by improving the material strength of the Cats Eyes Roads nail sheet and improving the structure of the Cats Eyes Roads nail sheet. At present, due to the limitations of material technology, an effective solution to greatly increase the strength of Cats Eyes Roads cannot be found. The improvement of the structure of the Cats Eyes Roads nail piece is to divide the original overall road stud structure into a number of isolated reflection units. In this way, after the road stud is partially damaged, only the local reflective effect will be affected, while other reflections will be affected. The unit can still work normally, so that the overall brightness of the road stud will not drop too much, thereby reducing the failure caused by local damage of the road stud.

Cats Eyes Roads sheet and road stud body separation failure is mostly caused by the loose combination of the road stud sheet and the road stud body. After repeated rolling by the vehicle, the joint part cracks under the action of alternating stress.

Improving the firmness between the spike piece and the spike body can effectively avoid such failures.

There are many reasons for the failure caused by the attenuation of the reflective brightness of the reflector. There are two main reasons, namely, the poor weather resistance of the reflector material and the abrasion of the outer surface of the reflector.

If the weather resistance of the material is not good, the shuttle mirror will be deformed after a period of use, and the angle formed by the four faces of the tetrahedron will change, which will cause the reflection efficiency to decrease or even no reflection. Improving the weather resistance of the spike material can effectively avoid the resulting failure.

The decrease in reflectance brightness caused by the wear of the reflector surface is due to the friction between the vehicle tire and the spike reflector, which makes the originally smooth surface of the reflector rough, thereby reducing the reflection efficiency of the reflector. Increasing the abrasion resistance of the reflector surface is an effective way to solve this type of failure mode.

Zhengzhou Southwest Ring Expressway was selected from the following aspects when choosing Cats Eyes Roads:

(1) The product has outstanding technical performance, strong resistance to failure, and good reflective effect.

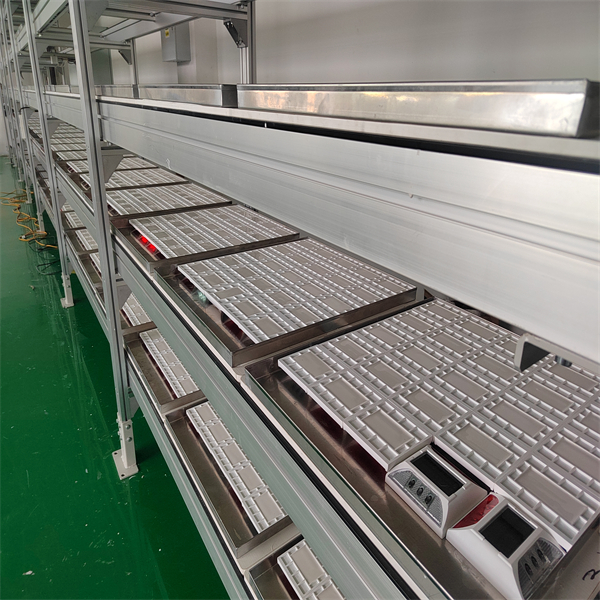

(2) The construction organization is simple and the construction period is short.

(3) The impact on the road and safe driving is small.

(4) Convenient for future maintenance and replacement.

(5) The product technology is mature and there are successful application cases

(6) The price of the product is moderate and cost-effective.

For the sake of ensuring traffic safety, the minimum reflective performance index of Cats Eyes Roads is required to be higher than the standard requirement. In terms of the appearance and construction requirements of Cats Eyes Roads, although footed Cats Eyes Roads can improve the bonding strength of spikes and pavement, considering that they must be installed on the formed pavement during installation, it will have a negative impact on the road surface and the construction period. The installation of Cats Eyes Roads is the finishing project of the entire expressway. The longer construction period may affect the completion of the entire project on schedule; once the Cats Eyes Roads body and the spike feet are separated, the spike feet may protrude out of the road surface. The tires of the driving vehicles cause secondary damage (the spike feet protruding from the road will scratch the tires), which increases the probability of tire blowouts and affects the safe driving of the vehicle; in addition, the footed Cats Eyes Roads does not damage the road after installation. It is difficult to take out the Cats Eyes Roads, and it is inconvenient for future maintenance and replacement. We chose the footless Cats Eyes Roads that can be directly pasted on the road.