What issues should be paid attention to when choosing Reflective Studs?

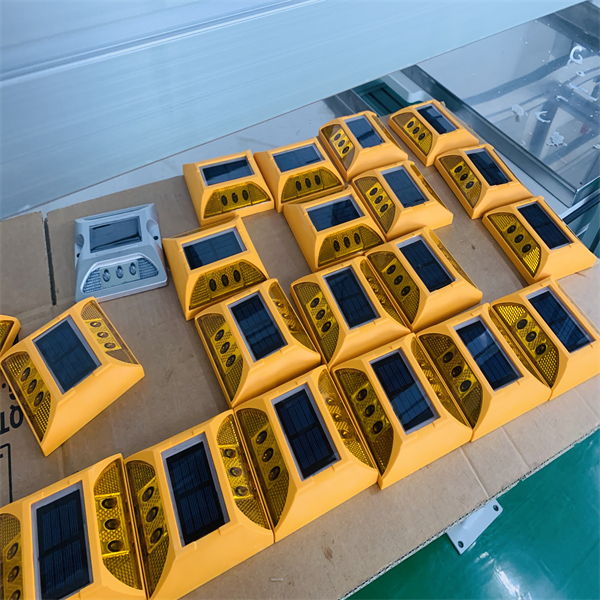

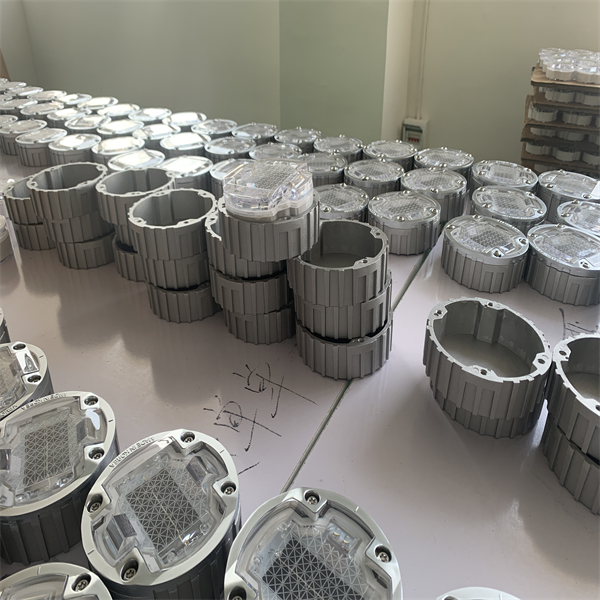

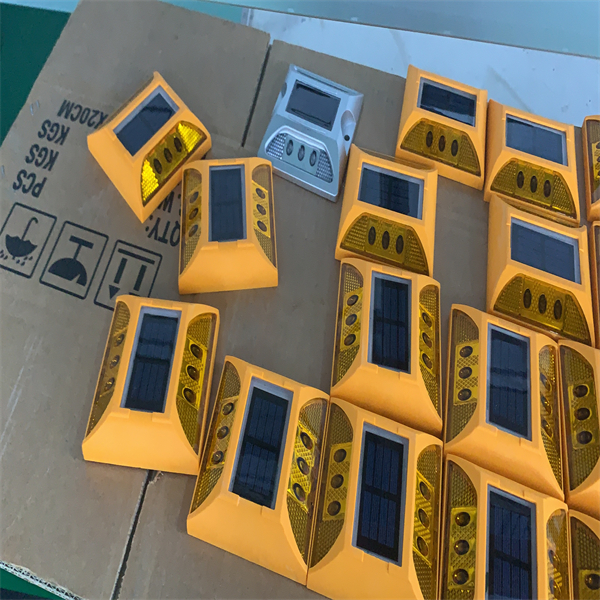

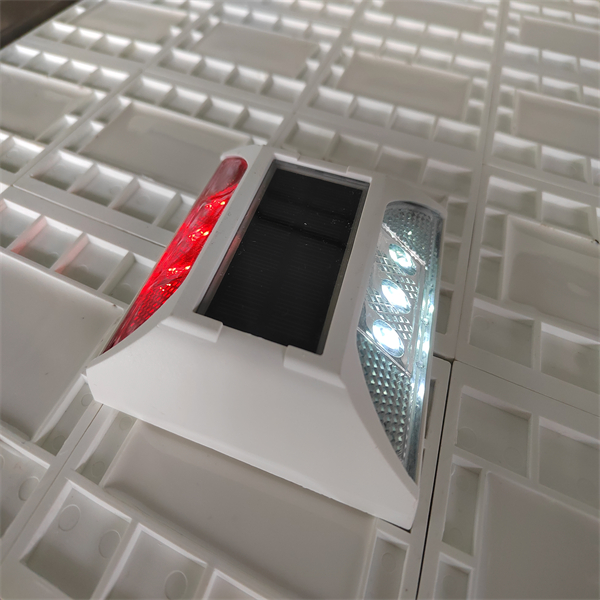

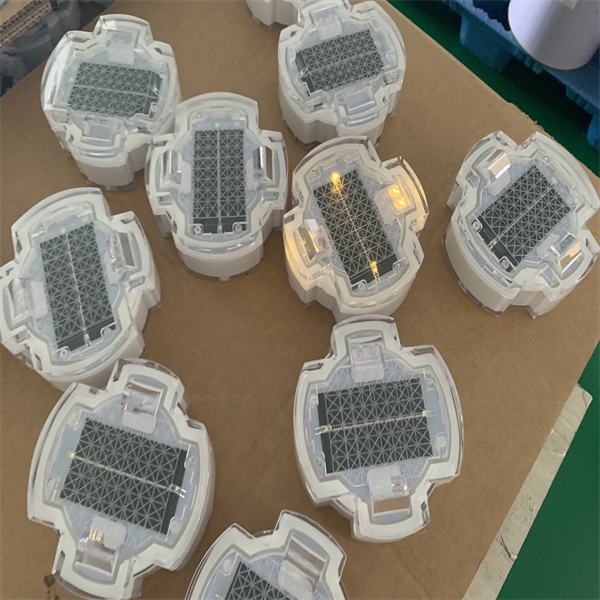

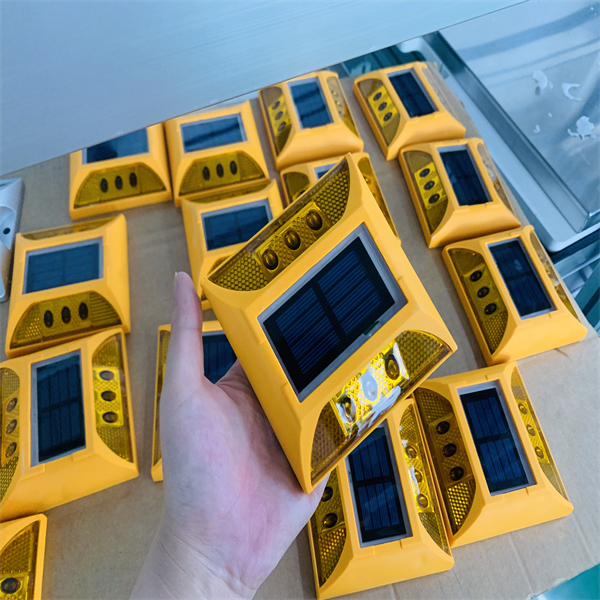

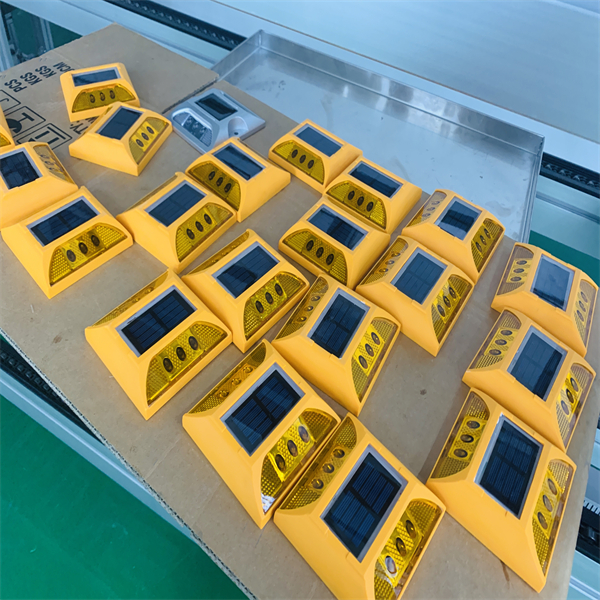

In addition, based on the analysis of the failure causes of Road Studs, it is proposed to Road Studs that the body of Road Studs must be made of a single material, which has good compressive strength and impact resistance. The shape of the Road Studs should be able to meet the bonding strength with the road surface or effectively reduce the lateral shear force that acts on the road studs when the vehicle is rolled: The Road Studs sheet must have a wear-resistant coating: The reflective structure of the Road Studs sheet can effectively prevent Road Studs The impact of local damage of the film on the overall brightness of the reflective film and other requirements.

When choosing Reflective Studs, it is considered from the following aspects.

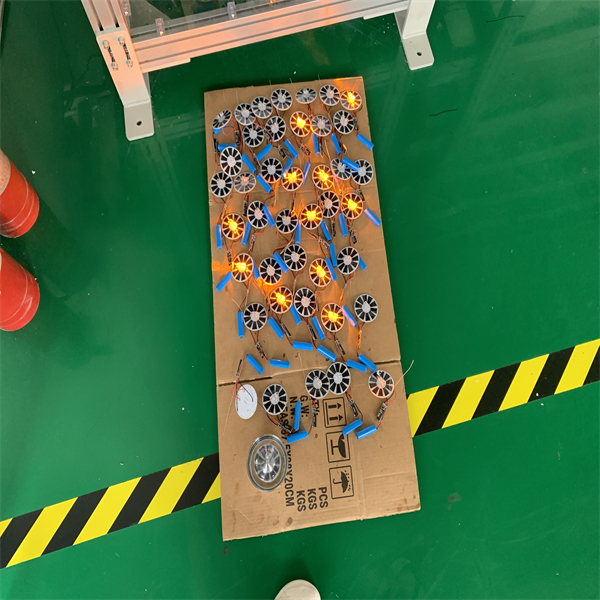

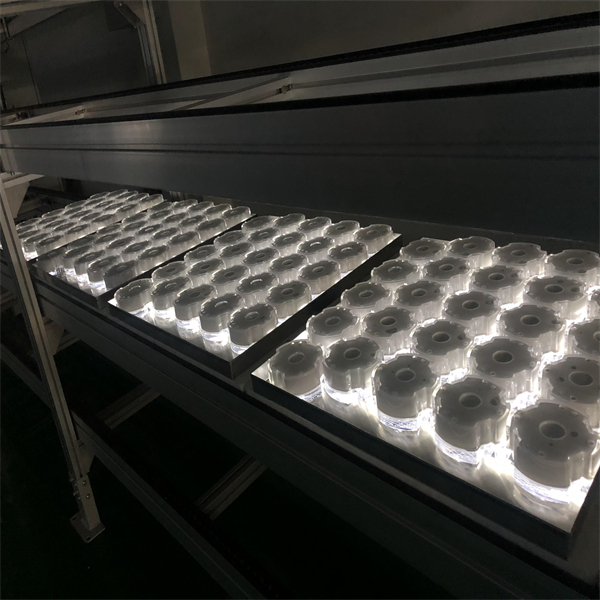

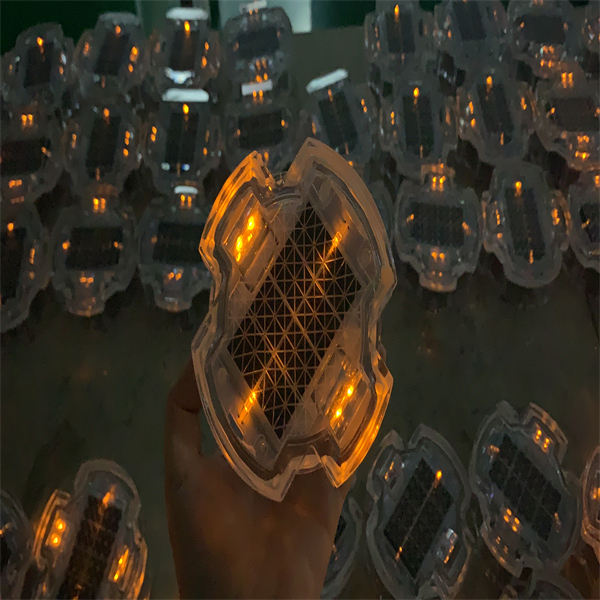

(1) The product has outstanding technical performance, strong resistance to failure, and good reflective effect.

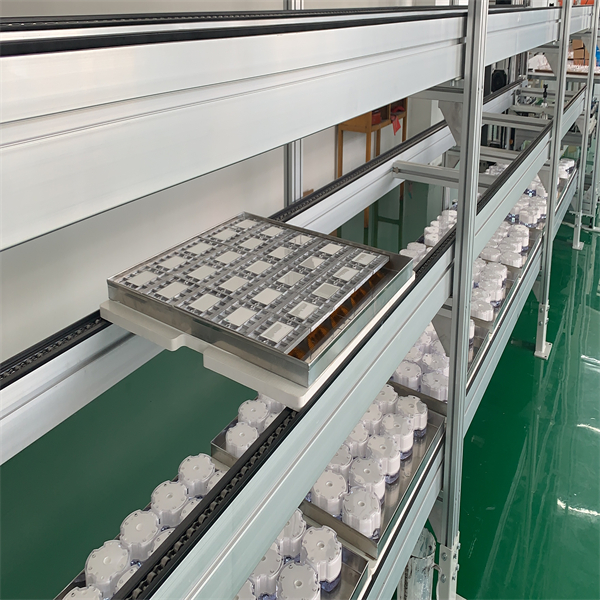

(2) The construction organization is simple and the construction period is short.

(3) The impact on the road and safe driving is small.

(4) Convenient for future maintenance and replacement.

(5) The product technology is mature and there are successful application cases

(6) The price of the product is moderate and cost-effective.

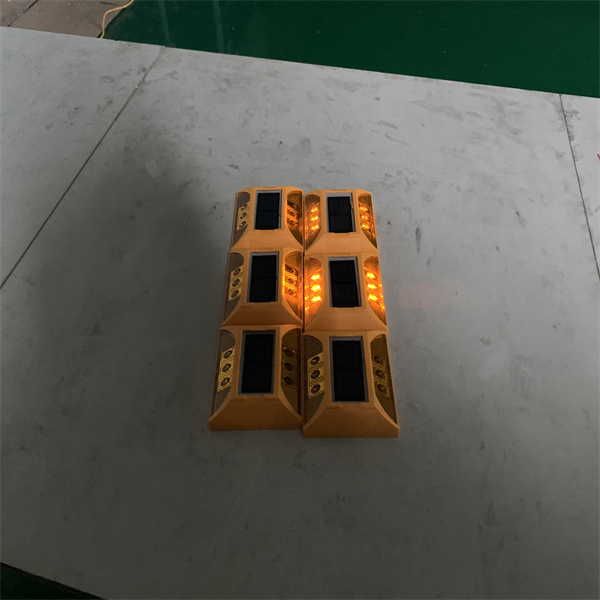

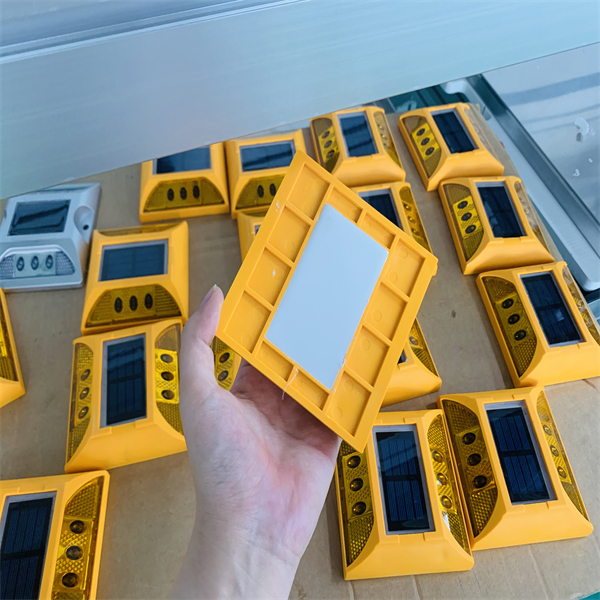

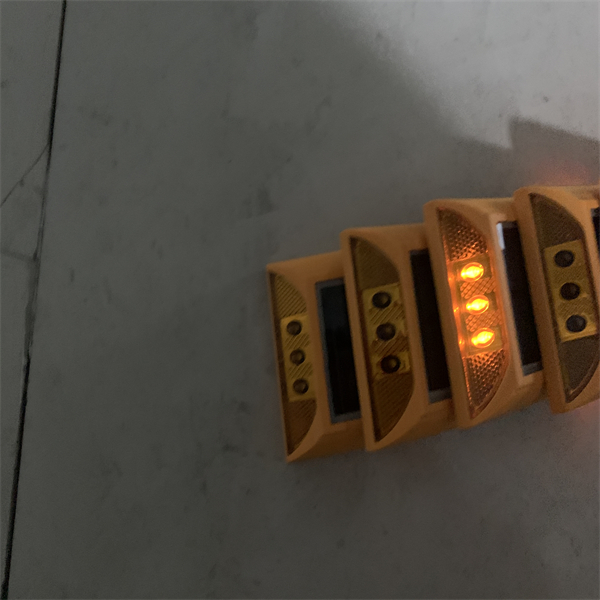

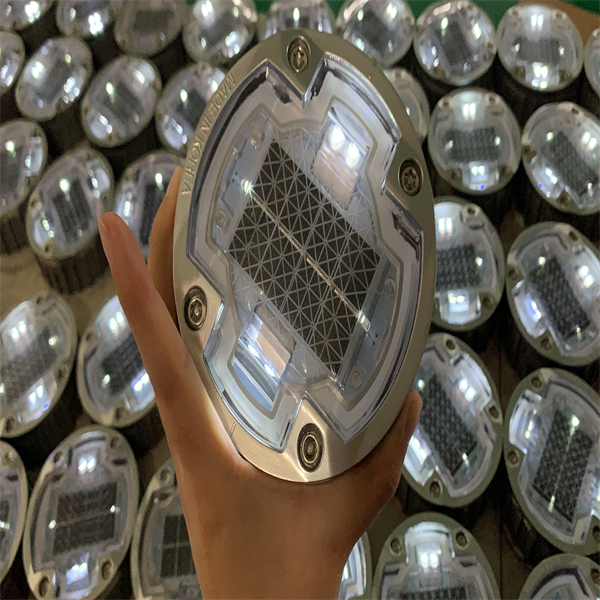

For the sake of ensuring traffic safety, the minimum reflective performance index of Road Studs is required to be higher than the requirements of the ministerial standards. In terms of the appearance and construction requirements of Reflective Studs, although footed Road Studs can improve the bonding strength of Road Studs and the road surface, considering that they must be installed on the formed road surface during installation, it has a negative impact on the road surface and the construction period is longer. , And Road Studs installation is the finishing project of the entire expressway, and its long construction period may affect the completion of the entire project on schedule. Once the Road Studs body and the Road Studs feet are separated, the spike feet may protrude out of the road, causing secondary damage to the tires of the driving vehicle (the spike feet protruding from the road will scratch the tires) and increase the chance of tire blowouts. Affect the safe driving of vehicles. In addition, it is difficult to remove the road studs without damaging the road surface after installation, and it is inconvenient for future maintenance and replacement. We chose the footless road studs that can be directly attached to the road surface.

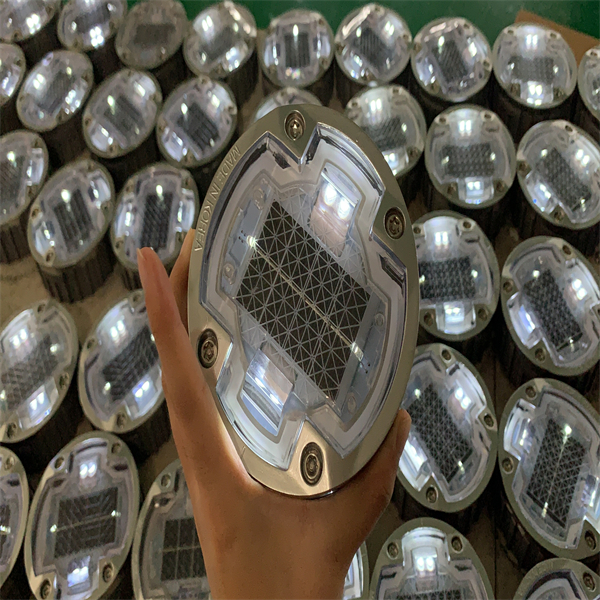

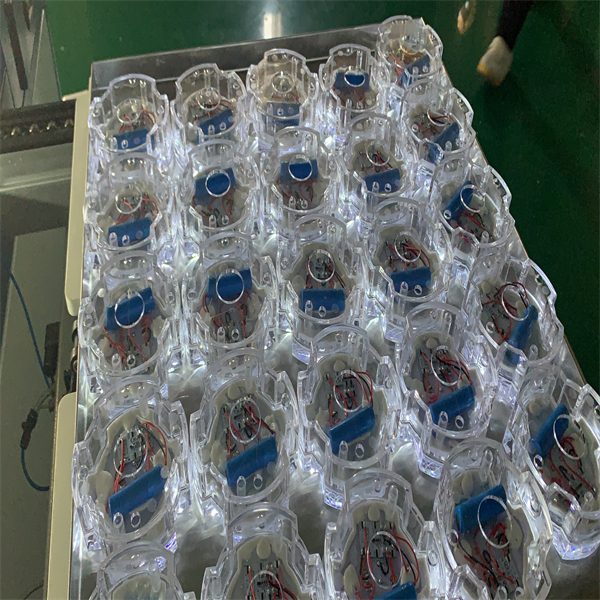

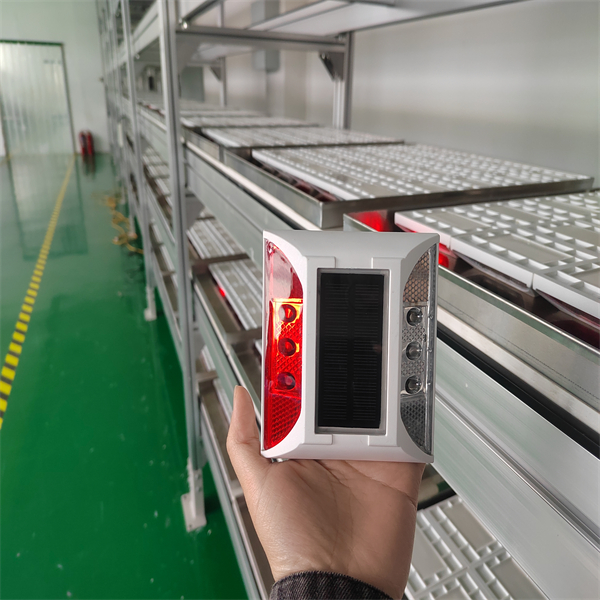

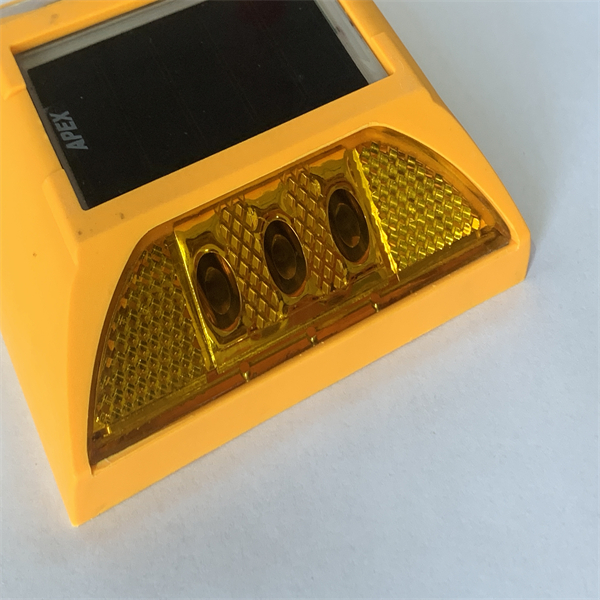

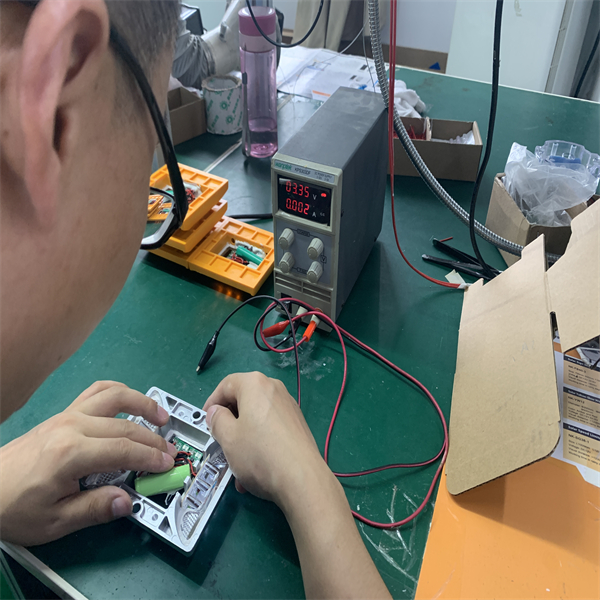

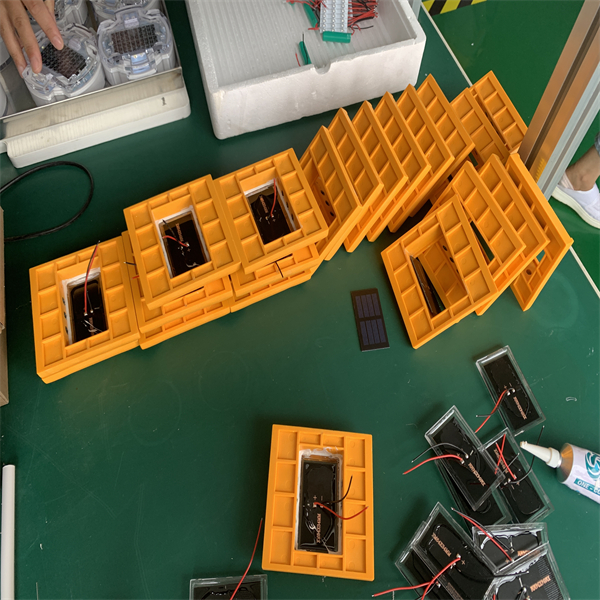

Regarding the material of Reflective Studs, considering that the deformation of the Road Studs sheet material will reduce the reflective performance of the road stud, we adopted a reflective sheet made of polycarbonate material with a small deformation coefficient and good weather resistance. Regarding the material of the Road Studs body, in order to reduce the failure of the Road Studs body, we have considered the use of the metal road Studs body, and then considered that the metal material Road Studs body has a higher unit price, and the use of the metal material Road Studs body The service life is much longer than the service life of the road studs made of engineering plastics, and one of the road studs and the road studs fails, and the road studs need to be replaced. The use of metal road studs does not extend the overall effectiveness of the road studs Service life, so Road Studs body uses the same polycarbonate spike body as Road Studs sheet.

Because the installation location of Road Studs (such as straight sections, curves, up-down ramps, etc.), the ratio of vehicle types on the road, and the driver’s driving habits, and many other uncertain factors will affect the service life of road studs, Road Studs do not It may provide a clear and effective service life guarantee for the product like a reflective film. According to relevant foreign experience, it is generally believed that no more than 5% after 1 year, and no more than 8% after 2 years-a dropout rate of 10% is acceptable. Therefore, when we selected Road Studs products, we learned about their domestic use and chose products with successful use cases.

In addition, based on the analysis of the failure causes of Road Studs, it is proposed to Road Studs that the body of Road Studs must be made of a single material, which has good compressive strength and impact resistance. The shape of the Road Studs should be able to meet the bonding strength with the road surface or effectively reduce the lateral shear force that acts on the road studs when the vehicle is rolled: The Road Studs sheet must have a wear-resistant coating: The reflective structure of the Road Studs sheet can effectively prevent Road Studs The impact of local damage of the film on the overall brightness of the reflective film and other requirements.

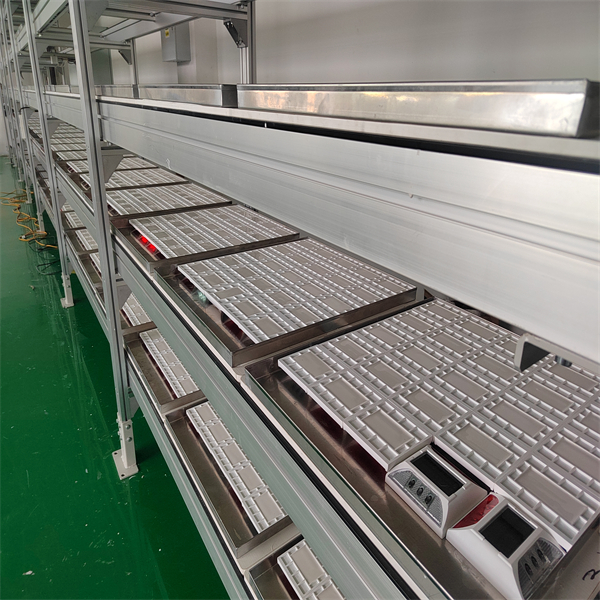

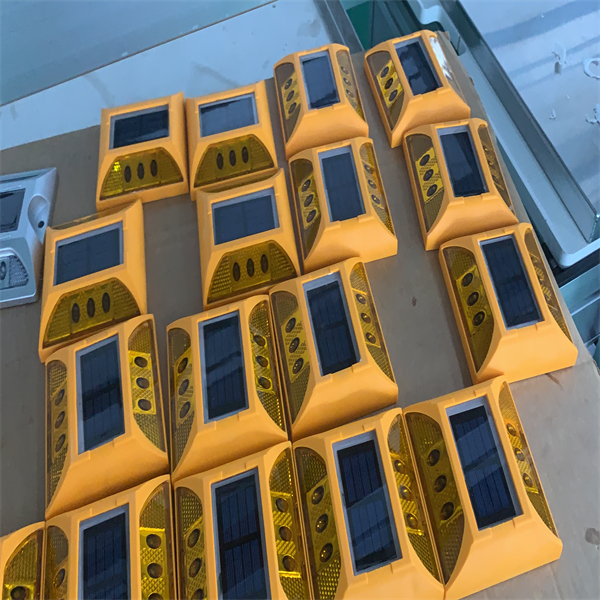

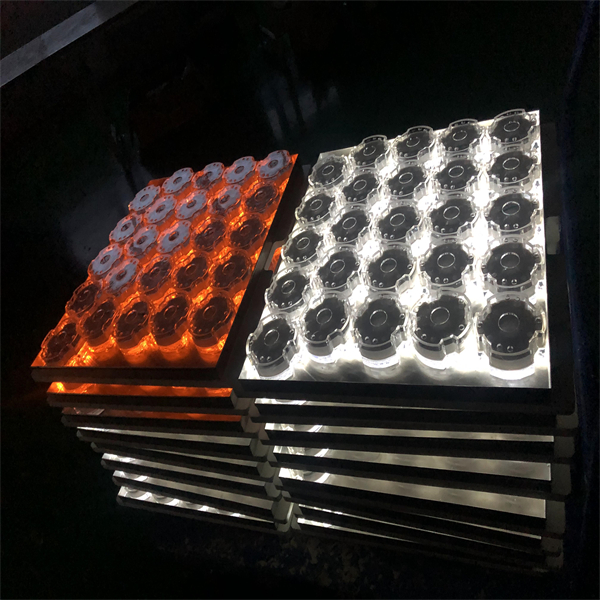

Based on the comprehensive evaluation of products that meet the above requirements, Reflective Studs produced by 3M Henan Ruichen Traffic Equipment Co, Ltd. were selected in the project. Ruichen Group has a good reputation in the field of retroreflective technology, and its Reflective Studs have high reflective properties. In terms of failure resistance, Reflective Studs’ spikes and spikes are made of polycarbonate. The angle between the reflective surface and the bottom of the Road Studs is the smallest among similar spikes, which can effectively reduce the impact on tires when they run over. The transverse shear force of the spike. The surface of the reflective sheet is coated with a wear-resistant coating, and the reflective sheet is divided into a number of isolated reflective units, which greatly reduces the possibility of failure due to the wear and partial damage of the Road Studs sheet. The Road Studs sheet and the Road Studs body are welded by ultrasonic welding technology, which improves the bonding strength of the Road Studs sheet and the Road Studs body. In terms of construction, Reflective Studs can be directly pasted on the road surface with asphalt glue. The construction is simple and meets the requirements of the construction period. In addition, we also learned about the use of Reflective Studs products by companies inside and outside the province. After getting the affirmation of its performance from other users, we chose this product.