Reflective road studs are a critical component of road safety infrastructure, significantly enhancing road visibility and providing continuous guidance for drivers, especially in low-light and adverse weather conditions. These studs leverage the retroreflective properties of glass beads or prisms to efficiently reflect vehicle headlight beams back towards the source, clearly delineating lane boundaries and potential hazards.

These markers are an indispensable part of modern traffic infrastructure, playing a vital role in accident reduction, improved lane discipline, and enhanced driver confidence. The meanings of reflective road stud colors are standardized within specific regions (e.g., North America, UK, Europe, and Australia), conveying crucial information about traffic flow, lane division, and emergency service locations. The evolution from passive to active (solar/LED) studs has not only boosted visibility but also opened new avenues for smart infrastructure integration, albeit with new considerations for durability and maintenance. Adherence to international standards (such as ASTM and EN) and best practices in installation and maintenance is paramount to ensuring the long-term effectiveness and sustained safety benefits of these devices.

Reflective road studs, commonly known as "cat's eyes" or "raised pavement markers" (RPMs), are small, durable devices embedded in the road surface. Their fundamental function is to enhance road visibility and provide continuous guidance for drivers, particularly at night or in adverse weather conditions such as fog, rain, or snow [1, 2, 3, 4, 5, 6, 7, 8, 9, 10]. They act as "silent communicators" on the road, promoting safety and efficiency by delineating lanes, centerlines, and edge lines [6, 11].

Beyond visual cues, road studs also provide unique tactile and audible feedback when a vehicle drives over them [2, 3, 4, 6, 11, 12]. This "rumble effect" [13] serves as an additional warning mechanism, alerting drivers to lane departure. This multi-sensory warning system is crucial as it provides a backup alert, especially in situations where a driver's visual attention might be compromised (e.g., fatigue, distraction, or heavy rain obscuring vision). This layered approach to safety means that road studs are more than just markers; they are active feedback mechanisms, making them more robust than simple painted lines. This characteristic suggests that future road stud designs may increasingly focus on optimizing these multi-sensory inputs.

The core principle behind reflective road studs is retroreflection, a phenomenon where light is reflected back towards its source rather than scattering in multiple directions [1, 14, 15, 16]. This ensures that when vehicle headlights strike a road stud, the light is efficiently returned to the driver's eyes, making the stud highly visible.

Glass beads represent an early and simpler form of retroreflection. When a beam of light strikes a glass bead, most of the light bounces off, but a significant portion passes through the front surface (the side facing the light source) and is refracted towards the center of the rear surface. Some of the light hitting the rear surface is internally reflected back through the front surface of the sphere and is again refracted onto a path parallel to the direction from which it came [14, 15, 16]. The particle size and density of the glass beads directly affect the reflection effect [14]. However, "open" glass bead systems in early trials lost all reflectivity in heavy rain, as the film of water deflected the light, and dirt collected in the tiny crevices [15].

Prisms (cube-corner reflectors) are more efficient. If a solid glass cube is cut along the diagonals of three adjoining faces, the basic cube-corner unit is formed, a squat triangular pyramid-shaped prism. Light entering the prism undergoes multiple internal reflections, effectively turning 180 degrees and returning precisely to the source [15, 16]. Modern microprismatic structures are highly efficient, maintaining stable reflective performance even with large angles of incident light [14, 16].

Retroreflection technology has seen significant advancements, from larger glass spheres (10-20mm diameter) and early cube-corner elements (around 6mm) in the 1920s, to highly refined microprismatic sheeting (0.15-0.25mm) developed by companies like Stimsonite and 3M in the 1980s [15]. Contemporary prismatic products can achieve significantly higher retroreflectivity, up to about 10 times that of encapsulated glass bead systems, offering superior brightness [15]. While prisms are more efficient, glass beads often provide a more uniform appearance with varying viewing angles [16]. The continuous evolution of retroreflection technology is directly linked to improved safety performance, indicating that ongoing innovation in material science is a primary driver for enhancing road safety infrastructure.

Reflective road studs are crucial for enhancing road safety by providing clear visual guidance, especially where traditional painted markings are obscured or insufficient.

Enhanced Visibility: They significantly improve visibility at night and in adverse weather conditions such as heavy fog, torrential rain, or heavy snowfall, where ordinary road markings may become blurred and difficult to see [1, 17, 2, 14, 4, 5, 6, 7, 18, 19]. Studies show that after installing reflective road studs, the driver's recognition distance of road markings can be increased by more than 3 times [2, 14].

Accident Reduction: This enhanced visibility directly translates into a reduction in accident rates. Research suggests that reflective pavement markers can reduce nighttime crashes by up to 30% [17, 6]. Some studies indicate that after installing edge lines, overall crashes decreased by 19%, fatalities and injuries by 37%, and nighttime crashes by 35% [20]. Cat's eye road studs are credited with reducing nighttime accidents by up to 47% and single-car accidents by up to 60% [4].

Improved Lane Discipline: By clearly marking lane edges and road boundaries, road studs help drivers stay within their designated lanes, preventing lane departure and reducing the risk of head-on collisions, especially on winding roads or in poorly lit areas [1, 17, 6, 18].

Hazard Indication and Speed Management: Different colors of road studs can indicate various types of hazards, alerting drivers to specific road conditions or upcoming changes [1, 17]. They also play a role in speed management, helping drivers gauge their speed and adjust accordingly, particularly in hazardous sections where road alignment changes suddenly or on sharp curves [1, 17].

Guidance During Power Outages: Unlike electric-powered solutions, passive reflective cat's eyes provide a fail-safe guidance system during power outages [4].

The colors of reflective road studs serve as a universal visual language on roads, conveying specific information to drivers about lane boundaries, traffic direction, potential hazards, and special road features. While the concept is global, the exact meanings and applications of these colors can vary significantly between different regions or countries.

In the United States, Canada, and generally in Australia (with some variations), the Manual on Uniform Traffic Control Devices (MUTCD) primarily dictates the use and meaning of road stud colors.

| Color / Combination | Meaning / Application (North America - MUTCD) |

|---|---|

| White | Lane markings, right pavement edge, separating same-direction traffic |

| Yellow | Separating opposing lanes, left pavement edge on one-way roads |

| Red | Areas closed to traffic, "Wrong Way" warning |

| Blue | Roadside fire hydrant location |

| Green | Emergency vehicle access (gated communities), bicycle lanes, safe exit/entry |

| White/Yellow + Red | Normal traffic flow (white/yellow); Wrong way/Do Not Enter (red) |

| White + Black | Reversible traffic flow lane restrictions (e.g., HOV lanes) |

The UK Highway Code has specific meanings for reflective road studs, commonly referred to as "cat's eyes."

| Color | Meaning / Application (UK - Highway Code) |

|---|---|

| White | Traffic lanes or road center line |

| Red | Left-hand edge of carriageway, danger/do not cross areas |

| Amber | Motorway/dual carriageway central reservation edge, warning areas |

| Green | Lay-bys, slip road entrances/exits |

| Green/Yellow (or Yellow) | Temporary lane adjustments (e.g., roadworks) |

| Blue | Emergency routes or lay-bys |

European standards, such as EN 1463-1, cover retroreflecting road studs in white, yellow, amber, red, and green [33, 34, 35]. This standard specifies initial performance requirements and laboratory test methods for these colors.

The Vienna Convention on Road Signs and Signals, aiming for international standardization, allows for some variations in road markings, including the use of white or yellow lines [36]. It stipulates that road markings must be less than 6mm high, and cat's eye reflectors no more than 15mm above the road surface [36].

Common European conventions generally align with the following colors:

It is worth noting that some sources mention ISO 3758 standards [33, 37, 38] in relation to road stud standards; however, ISO 3758 actually pertains to textile care labeling symbols, not reflective materials for road markings, which may be a misapplication in some documentation.

Australia generally follows European conventions for road stud colors [21].

Road studs, regardless of color, are also used in various special applications beyond standard traffic management, including marking hazardous curves, pedestrian crossings, roundabouts, and even in outdoor spaces like parks and pathways for aesthetic and safety purposes [7, 9, 21, 30].

The significant regional variations in road stud color meanings can impose a cognitive burden and safety risk on international drivers. This disparity highlights the need for greater standardization globally, or at least enhanced driver education specific to locations. For instance, red signifies "left edge of the road" in the UK [27], while in the US, it means "do not enter/wrong way" [21]. Similarly, the application of yellow differs for central reservations and tram tracks. Even the Vienna Convention [36], intended for universality, permits variations. This inconsistency can lead to confusion and misinterpretation for drivers crossing regions, thereby increasing accident risk. While complete global standardization may be impractical, this observation underscores the extreme importance of robust localized driver education programs for both residents and visitors. For autonomous vehicles, this variability presents complex challenges for universal programming, suggesting a need for highly adaptive recognition systems or a stronger push for international consensus on fundamental road marking semantics.

The historical evolution of road marking color codes within the MUTCD demonstrates a continuous, data-driven effort to optimize driver comprehension and safety, reflecting an adaptive approach to infrastructure design. [24] provides a detailed history of MUTCD changes, particularly the shift from white to yellow for centerlines separating opposing traffic in the 1970s. The rationale for this change was improved contrast, consistency with symbolic warning colors, and standardization. This was not an arbitrary change but a deliberate adjustment based on accumulated experience and safety objectives. This historical perspective reveals that road safety standards are dynamic, not static. They are continually refined as traffic conditions, human factors research, and technological capabilities evolve. This means that current color codes are the product of iterative improvements aimed at maximizing clarity and safety. Furthermore, it suggests that future advancements in driver assistance systems (e.g., augmented reality displays) or smart infrastructure could lead to further re-evaluation or enhancement of these color codes, potentially even introducing dynamic or context-aware markings to further optimize driver behavior.

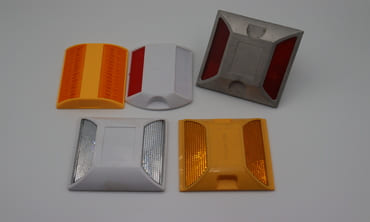

The choice of material for reflective road studs significantly impacts their durability, visibility, and suitability for various road environments.

| Characteristic / Material | Plastic | Aluminum | Ceramic | Glass |

|---|---|---|---|---|

| Durability | Medium (prone to UV/temp damage) | High (robust, withstands heavy traffic) | Very High (withstands >30 tons, extreme temps) | Medium (lower impact resistance) |

| Reflectivity | Good (can degrade) | Superior (smooth surface, often prismatic) | High (embedded glass beads) | Very High (micro-prism structure, >300 mcd·lx⁻¹·m⁻²) |

| Weather Resistance | Medium (UV, low-temp brittleness) | High (corrosion-resistant, weatherable) | Very High (waterproof, corrosion-resistant, -40°C to 70°C) | High (excellent in rain) |

| Cost | Low | Medium | High | High |

| Installation | Easy (adhesive) | Medium (mechanical fixation) | Easy (adhesive/drilling) | Easy (adhesive/drilling) |

| Typical Application | Temporary, low-traffic | High-traffic, highways, corrosive areas | High-traffic, heavy-load, extreme temps | High visibility areas (pedestrian crossings, tunnels) |

| Lifespan | Short (temporary use ≤1 year) | Long | Very Long | Long |

The selection of road stud material is a critical engineering decision that requires a comprehensive trade-off analysis to balance initial cost, long-term durability, and specific environmental and traffic demands. Sources like [5, 39, 32, 40, 18, 41] collectively illustrate the varied characteristics of different materials. Plastic studs are inexpensive and easy to install but lack durability [39, 40]. Aluminum is robust and long-lasting, though installation can be more involved [39]. Ceramic offers extreme durability but may come at a higher cost [40, 18]. Glass provides superior reflectivity but has lower impact resistance [40]. [19] explicitly advises choosing based on traffic flow, use environment (temperature), and function. This implies there is no universally "best" road stud material. Informed decisions require a detailed assessment of the intended application, traffic volume, prevailing climate (e.g., extreme temperatures, snowplow operations), and budget. Misapplication of materials (e.g., using plastic in high-traffic areas) will inevitably lead to premature failure, increased maintenance costs, and compromised safety, turning initial savings into long-term liabilities. This highlights the importance of looking beyond basic performance in procurement specifications to consider lifecycle costs and environmental suitability.

The advent of active (solar/LED) road studs marks a paradigm shift towards proactive safety and smart infrastructure, but also introduces complex challenges related to energy management and the longevity of electronic components in harsh environments. While passive studs offer visibility up to 90 meters, active studs extend this to 900-1000 meters [4, 7, 44], increasing driver preview time tenfold [46, 47]. This enhanced visibility directly contributes to improved safety. However, active studs rely on solar panels and batteries [2, 41, 45, 43], whose lifespan is influenced by these electronic components [45]. Furthermore, [41] notes that making solar studs "pressure resistant" is a challenge due to their electronic nature. Consequently, deploying active studs requires a more sophisticated maintenance approach, including monitoring battery health, solar panel efficiency, and LED functionality, in addition to physical integrity. This shift necessitates new skills for maintenance personnel and can lead to higher long-term operational costs if not managed properly. Nevertheless, it also paves the way for "smart road" functionalities, where studs can integrate with Intelligent Transportation Systems (ITS) to provide real-time data on traffic flow or hazards, transforming them from static markers into dynamic communication nodes.

Road studs are designed to withstand harsh road environments, including heavy traffic, extreme weather, and abrasive elements [39, 32, 18, 8, 33].

To ensure consistent performance and safety, reflective road studs must adhere to stringent technical specifications, particularly concerning their reflective capabilities.

Retroreflectivity is the primary measure of a road stud's effectiveness, quantifying how efficiently it reflects light back to its source, typically vehicle headlights [33]. Higher retroreflectivity directly translates to greater visibility for drivers in adverse conditions [33].

Color Consistency and Visibility: Reflective materials must maintain consistent color and visibility throughout their lifespan, resisting degradation from UV light and harsh weather conditions [33].

Performance in Different Weather Conditions: Road studs must maintain their reflective capabilities under various weather conditions (rain, fog, snow) and should not degrade significantly under moisture or freezing temperatures. They are specifically tested to withstand water immersion [33]. It is important to note that wet retroreflectivity cannot reliably predict dry retroreflectivity [48].

Durability and Longevity: The reflective surface must be resistant to wear and tear, UV radiation, and chemical degradation from vehicle emissions and road salt. Standards typically require the reflective surface to last for at least 5 years under normal traffic conditions without significant degradation of reflectivity [33].

Resistance to Vehicle Impact: Road studs must be strong enough to resist damage from vehicle tires, high-speed traffic, and heavy loads. Their base design often incorporates shock absorption features [33].

Adherence to national and international standards is crucial for ensuring consistent performance and safety across different regions.

The comprehensiveness and rigor of international road stud standards underscore their critical function as safety-critical components, necessitating strict adherence to quality assurance throughout their lifecycle. Sources like [31, 7, 33, 34, 53, 13, 51, 52, 50, 49, 54, 35] detail extensive requirements for performance and physical properties (retroreflectivity, compressive, flexural, impact, abrasion resistance, color consistency, weatherability). The repeated emphasis on ASTM D4280 and EN 1463-1, including specific test methods and classification systems, highlights the depth of these standards. These standards are not mere suggestions; they are fundamental benchmarks that ensure road studs operate reliably under extreme traffic and environmental stresses. Non-compliance can lead to premature failure, reduced visibility, and increased accident risk, potentially incurring significant legal and financial liabilities for road authorities and manufacturers. This further emphasizes that the procurement and deployment of road studs must strictly adhere to these technical specifications, stressing the importance of certified products and robust quality control processes.

The explicit distinction and separate test methods for dry versus wet retroreflectivity reveal the persistent and complex engineering challenge in achieving consistent all-weather visibility, indicating ongoing research needs and potential limitations of current technology. [48] explicitly states that "wet retroreflectivity cannot be predicted by dry retroreflectivity" and that dry performance is "almost always higher." It also notes that even markings "specifically designed for wet nighttime performance" have "relatively short" durability. The existence of dedicated ASTM test methods for wet conditions (E2177, E2832) further underscores this challenge. While road studs are crucial for improving visibility in adverse weather [2, 14], maintaining optimal performance in rain remains a significant hurdle. This observation suggests that current technology may have inherent limitations in providing high retroreflectivity under continuously wet conditions. Therefore, ongoing R&D is vital for innovating materials and designs that can overcome this challenge, potentially leading to breakthroughs in hydrophobic surfaces or more robust wet-weather optics. For road authorities, this implies that for wet-weather critical areas, current maintenance schedules may need to be more frequent, impacting long-term operational costs and requiring careful cost-benefit analysis in different climates.

Correct installation is paramount for the long-term stability, effectiveness, and safety contribution of reflective road studs. It directly impacts the stud's lifespan and performance.

Correct installation is not merely a procedural step but a foundational determinant of a road stud's long-term safety performance and overall cost-effectiveness, meaning that initial investment in quality installation yields significant lifecycle benefits. Sources like [32, 56, 19] consistently emphasize the importance of meticulous surface preparation, proper adhesive application, precise positioning, and adequate curing time. [32] explicitly warns that "improper installation... can cause premature detachment or misalignment, which reduces effectiveness and may cause safety hazards." Furthermore, [60] notes that bond failure can lead to "considerable maintenance costs" and that detached markers can become projectiles, posing a safety risk of vehicle damage or motorist injury. This establishes a direct causal link: high-quality initial installation minimizes future maintenance needs and maximizes the safety benefits of road studs. Conversely, cutting corners during installation leads to a cascade of negative consequences, including reduced visibility, increased accident potential, higher repair costs, and potential legal liabilities. This observation strongly advocates for comprehensive training of installation crews, strict adherence to manufacturer guidelines, and rigorous quality control during deployment as fundamental components of a cost-effective and safety-first infrastructure strategy.

Consistent and effective maintenance is crucial for ensuring the long-term stability, reflective performance, and safety contribution of road studs.

The lifespan and sustained performance of road studs depend on a complex interplay of material science, environmental stresses, and proactive, data-driven maintenance, indicating the need for integrated asset management systems. [45] details the varying lifespans of individual components within solar studs (solar panels, batteries, LEDs), which influence the overall stud lifespan (3-12 years). [32] emphasizes that choosing high-quality materials, correct installation, and regular cleaning/inspection are key to long-term stability. Sources like [56, 61] highlight the necessity of periodic inspections, prompt replacement of damaged units, and cleaning, especially after adverse weather. [60] explicitly mentions freeze-thaw cycles and salt intrusion as factors contributing to adhesive bond degradation. Effective road stud management extends beyond simple passive replacement. It requires a sophisticated, predictive maintenance strategy that accounts for material degradation over time, specific environmental impacts (e.g., snowplow damage in winter regions [60, 30]), and the cumulative effects of traffic wear. The mention of "smart maintenance technologies" [45, 61] points to a future where real-time monitoring and data analytics can optimize maintenance schedules, shifting from reactive repairs to proactive asset management. This approach not only extends the lifespan of road studs but also ensures continuous optimal performance, maximizing safety and minimizing overall operational costs.

Numerous studies and meta-analyses demonstrate the positive impact of reflective road studs on road safety, particularly in low-visibility conditions.

One of the primary functions of road studs is to clearly delineate lanes and road boundaries. This is particularly beneficial on winding roads or in poorly lit areas, where they act as visual guides, preventing lane departure and reducing the risk of head-on collisions [1, 2]. They also play a role in speed management and hazard indication [1, 2].

Reflective road studs are an indispensable component of modern road safety infrastructure, playing a critical role in enhancing road visibility and guiding drivers through their unique retroreflective principles and standardized color-coding systems. From traditional passive glass bead and prismatic studs to advanced solar/LED active studs, continuous technological advancements have significantly improved driving safety at night and in adverse weather, effectively reducing accident rates.

The colors of road studs carry specific meanings across different regions globally, and despite regional variations, their core objective remains to clearly convey traffic information, lane boundaries, and potential hazards. This visual language, complemented by tactile and audible feedback, provides drivers with multiple layers of warning, especially when fatigued or distracted.

The choice of road stud material (plastic, aluminum, ceramic, glass) directly influences its durability, compressive strength, weather resistance, and cost-effectiveness, requiring a careful trade-off based on specific traffic volumes and environmental conditions. Concurrently, strict adherence to international standards like ASTM and EN, which ensure high-quality requirements for retroreflectivity, luminous intensity, and physical properties, is fundamental to their long-term effectiveness.

However, the performance of road studs is not a one-time achievement. Correct installation practices, including thorough surface preparation, selection of appropriate adhesives, and precise spacing, are crucial for ensuring their longevity and safety benefits. Furthermore, regular maintenance, such as cleaning, inspection, and prompt replacement of damaged studs, is essential to sustain their optimal reflective performance. With the evolution of smart maintenance technologies, future road stud management will become even more efficient and predictive.

Despite some studies showing mixed accident impacts under specific conditions, the overall evidence strongly supports the significant positive role of reflective road studs in reducing nighttime accidents, improving lane discipline, and enhancing driver confidence. They are a cornerstone for achieving safer and more efficient road networks, and with ongoing technological innovation and gradual harmonization of global standards, their role in future traffic safety will continue to strengthen.