The inherent dangers of driving, especially in low-light conditions, adverse weather (such as fog, rain, or snow), and on winding or poorly lit roads, represent a significant global challenge to traffic safety. In these scenarios, traditional road markings can become obscured or entirely invisible, dramatically increasing the risk of accidents [1, 2, 3, 4]. To counter these challenges, non-powered reflective road markers—commonly known as "cat's eyes" or "raised pavement markers (RPMs)"—have emerged as a simple yet exceptionally effective solution designed to enhance road visibility and safety.

What makes these devices unique is their passive nature; they operate without requiring an external power source [1, 5, 6, 7]. They function by reflecting light from vehicle headlights, offering drivers continuous visual guidance and warnings. This effectively reduces risks when conventional markings are insufficient to provide clear direction. These non-powered reflective road markers play a fundamental role in modern road infrastructure, acting as "silent communicators" that deliver crucial road information precisely when it's most needed [1, 6, 8, 9]. Their constant presence and continuous reflection—this "silent communication"—are particularly vital when other visual cues fail, such as during heavy rain or dense fog. This always-on utility distinguishes them from active warning systems, with their reliability in harsh conditions being their core value proposition.

Non-powered reflective road markers are small, reflective devices installed on road surfaces designed to enhance visibility and guide drivers by reflecting light from vehicle headlights back towards their source [1, 5, 6, 8, 9]. They are popularly known as "cat's eyes" due to their inventor Percy Shaw's inspiration [5, 6].

The primary functions of these road markers are multifaceted, collectively forming a comprehensive road safety strategy:

Non-powered reflective road markers significantly improve road visibility by reflecting vehicle headlight beams, particularly at night or in adverse weather conditions. In complete darkness or severe weather like fog, heavy rain, or snow, ordinary road markings may become unclear. However, the reflective properties of these markers ensure road markings remain distinctly visible, assisting drivers in identifying lane positions and navigating curves and intersections more safely [1, 2, 3, 4].

One of the core functions of road markers is to clearly mark lane edges. On winding mountain roads or in areas with poor lighting, these markers act like rows of "invisible barriers," constantly reminding drivers to stay within their correct lane, effectively reducing head-on collisions caused by lane departure [1, 2, 10]. Different colored markers are used to indicate specific lane functions; for instance, white reflectors delineate center lines and lane markings [1, 5, 11, 12].

Road markers also assist drivers in managing their speed. When road alignments change abruptly, markers delineating lanes and road edges help drivers detect and adjust their speed in a timely manner. In hazardous sections such as sharp bends or steep gradients, the presence of these markers can reduce accident rates due to speeding by approximately 20% [1, 2, 13].

Distinct colors of road markers play a crucial role in indicating various hazards. For example, red markers indicate the left edge of the road, alerting drivers to the boundary; amber markers delineate median barriers in two-way lanes, warning vehicles not to cross indiscriminately. This color-coding system enables drivers to instantly identify potential dangers and prepare in advance [1, 2, 5, 11, 12].

When vehicles drive over certain types of road markers (such as cat's eyes with a resilient rubber housing), they provide distinct tactile and auditory feedback to the driver [3, 5, 9]. This immediate signal serves as an important warning, alerting drivers that their vehicle is veering off the road or out of its lane, prompting them to take timely corrective action to prevent accidents. This multi-sensory feedback mechanism provides crucial redundancy, especially for fatigued or distracted drivers, or in extremely low visibility conditions where visual cues might still be challenging. The deliberate incorporation of these additional sensory cues in certain non-powered markers (like traditional cat's eyes with rubber housings) enhances their overall effectiveness as safety devices and demonstrates a holistic approach to driver guidance.

Road reflectors, or cat's eyes, operate on the principle of retroreflection, which is the process of reflecting light back towards its source [1, 4, 5, 14, 15]. When vehicle headlights shine on the road marker, the reflective elements within the marker direct the light back to the driver's eyes, making the marker clearly visible even from a distance [1, 4, 6, 9].

A typical non-powered road marker generally consists of a reflective lens (made of glass or plastic) and a durable housing (e.g., cast iron, plastic, aluminum) that protects the reflective elements and secures the marker to the road surface [1, 4, 5, 6]. Some cat's eye designs cleverly incorporate self-cleaning mechanisms where the reflective element retracts and is wiped by brushes as vehicles pass over them, with even patent updates mentioning the use of collected rainwater for spraying to further clean them, ensuring they remain consistently bright and reflective [5, 6].

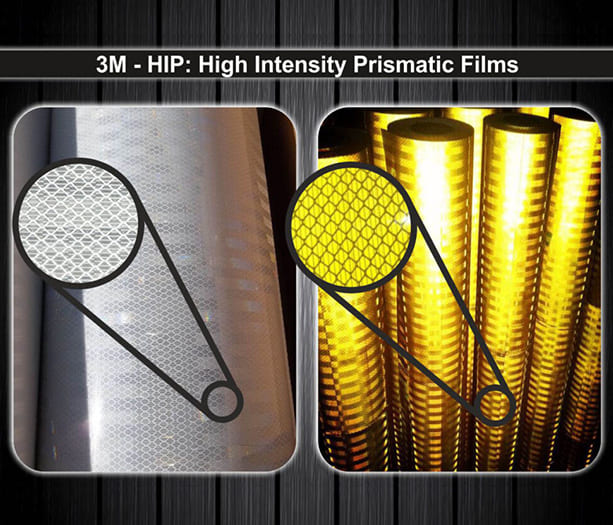

Percy Shaw's invention in the 1930s [5, 6] utilized glass beads and a mechanical cleaning system [5]. Subsequent developments, such as microprismatic sheeting [14], offered retroreflectivity up to 10 times higher than encapsulated glass bead systems [14]. This indicates that even seemingly simple devices like road markers are subject to continuous innovation in material science and optical engineering to improve performance and address limitations (like dirt buildup or wet weather performance). This ongoing trend of innovation underscores the continued importance of these devices and the investment in making them more effective and reliable, even as advanced vehicle technologies emerge.

The choice of material significantly impacts a road marker's durability, reflectivity, cost, and ideal application scenario [16, 17].

A detailed analysis of each material's pros and cons reveals that there isn't a single "best" material. Instead, the optimal choice is a strategic decision that depends on a complex interplay of factors, including traffic volume, environmental conditions (temperature, humidity, corrosivity), expected lifespan, specific application (e.g., temporary, pedestrian crossing, highway), and budget. This underscores the need for a tailored approach in infrastructure planning, where on-site assessment and a thorough understanding of material properties are paramount to maximizing safety, durability, and cost-effectiveness.

| Material Type | Key Characteristics | Durability/Lifespan | Reflectivity Level | Impact Resistance | Cost (Relative) | Ideal Application Scenarios |

|---|---|---|---|---|---|---|

| Plastic | Lightweight, cost-effective, easy to install, impact-resistant plastic polymers [8, 16, 17, 18] | Temporary, recommended for project durations ≤1 year [18] | Good | Prone to damage, susceptible to UV and extreme temperature degradation [16, 18] | Low [16, 18] | Temporary marking, low-traffic areas, rapid deployment [8, 16, 17, 18] |

| Ceramic | High strength, compression-resistant, extreme temperature resistance (-40°C to 70°C), waterproof, corrosion-resistant [18, 19] | 5-8 years [18], long lifespan [19] | Excellent [19] | Withstands over 30 tons of heavy pressure [18] | Medium [18] | High-traffic, heavy-load areas (highways, expressways, pedestrian crossings) [8, 17, 18, 19] |

| Aluminum | Robust, durable, corrosion-resistant, high-quality aluminum alloys, often integrated with glass/prismatic reflectors [1, 8, 16, 17, 18] | Long lifespan [16] | Superior [16] | Robust [16] | Medium-High [21] | High-traffic areas, harsh outdoor environments, corrosive environments (coastal roads) [1, 16, 17, 18] |

| Glass | Tempered glass, microprismatic structure, high light transmittance (≥92%), good reflectivity in rain [8, 18] | Long lifespan [8] | Very High (>300 mcd·lx⁻¹·m⁻²) [18] | Relatively lower impact resistance (flexural strength ≥120 MPa) [18] | High [21] | High visibility required areas (pedestrian crossings, tunnel entrances/exits) [8, 17, 18] |

The contribution of reflective road markers to road safety is significant and quantifiable, with their effects evident in multiple areas:

By reflecting vehicle headlights, road markers significantly enhance visibility, particularly at night or in adverse weather (fog, rain, snow). This allows drivers to clearly see road boundaries and lane lines, increasing the recognition distance of road markings by more than 3 times [2, 4]. This extended visibility provides drivers with crucial "reaction time," enabling them to respond promptly to road conditions, curves, and potential hazards [2, 13, 22].

By clearly delineating lane edges, road markers serve as visual guides, reminding drivers to stay within their correct lane. Studies indicate that on roads with clearly marked lane boundaries using these markers, lane departure accidents are reduced by approximately 25% [2]. This is particularly effective in mitigating head-on collisions [2].

Road markers assist drivers in judging and adjusting their speed, especially where road alignments change abruptly. In hazardous sections like sharp bends or steep gradients, their presence can reduce accident rates due to speeding by about 20% [2]. Although some studies on active markers show no statistically significant change in average vehicle speeds [13], improved visibility can heighten drivers' perception and awareness of speed [13].

Different colored road markers (red for left edge, amber for median barriers, white for lane lines, green for traversable edges) provide immediate warnings and guidance, allowing drivers to anticipate and react to potential hazards [1, 2, 5, 11, 12].

Overall, research by the Texas Transportation Institute and the National Cooperative Highway Research Program (NCHRP) indicates that reflective pavement markings can reduce nighttime accidents by up to 30% [2, 9]. Specific findings include:

While the overall benefits of road markers are widespread, some studies also present complex results [25, 26]. For instance, a Texas study observed negative impacts (15-30% increase in nighttime crashes) [25]. Another Texas study showed mixed results, with significant reductions in accidents at some locations and increases at others [25]. The New York State Department of Transportation reported a 26% reduction in nighttime accidents only when RPMs were installed "selectively" based on wet-weather nighttime crash history; non-selective installation showed no significant effect [25, 26]. In low-volume or sharp curve areas, RPMs could sometimes be associated with negative effects (e.g., a potential 26% increase in nighttime crashes for AADT between 5,000-15,000 vehicles and curvature greater than 3.5 degrees) [26].

These mixed results suggest that the effectiveness of road markers is not uniform but highly dependent on factors such as installation strategy (selective vs. non-selective), traffic volume, road geometry (curves), and weather conditions (wet vs. dry). This implies that successful implementation requires careful planning and analysis of specific road characteristics, rather than just universal application.

Furthermore, retroreflectivity under wet pavement conditions is critical: it cannot be predicted by dry pavement retroreflectivity, and its durability is often shorter [27]. Some markings designed for wet-night performance have dropped to 100 mcd/m2/lx or less in retroreflectivity after the first year [27]. This indicates that the key lies in maintaining retroreflectivity under the most challenging conditions. This points to a crucial area for future development and maintenance. Road authorities must prioritize materials and designs specifically addressing wet-weather performance to ensure continuous safety benefits, particularly given that many accidents occur under these conditions.

| Safety Benefit Category | Observed Reduction/Impact | Source/Study | Conditions/Remarks |

|---|---|---|---|

| Total Nighttime Accidents | Up to 30% reduction [2, 9] | Texas Transportation Institute, NCHRP [2, 9] | Sections of roads with road markers installed [2] |

| Lane Departure Accidents | 25% reduction [2] | Relevant Research [2] | Roads with clearly delineated lane boundaries using markers [2] |

| Speeding-Related Accidents | Approximately 20% reduction [2] | Relevant Research [2] | Hazardous sections (sharp bends, steep gradients) [2] |

| Total Accidents (Multilane) | CMF = 0.825 [24] | FHWA [24] | Multilane roads [24] |

| Injury Accidents (Freeway) | CMF = 0.881 [24] | FHWA [24] | Freeways [24] |

| Wet Pavement Accidents (Freeway) | CMF = 0.861 [24] | FHWA [24] | Freeways [24] |

| Total Pavement Marking Accidents | Average 21% reduction [23] | Miller Meta-analysis [23] | Considered reliable studies [23] |

| Added Edgelines and Centerlines | 36% reduction in crashes [23] | Bali et al. [23] | Rural two-lane roads [23] |

| Nighttime Accidents (Selective Installation) | 26% reduction [25, 26] | New York State DOT [25, 26] | Selectively installed based on wet-weather nighttime crash history [25, 26] |

| Nighttime Accidents (Low Traffic/Sharp Curves) | Potential 26% increase [26] | NCHRP [26] | AADT 5,000-15,000 and curvature >3.5 degrees [26] |

Correct installation is paramount for the long-term stability, effectiveness, and safety contribution of reflective road markers. Improper installation can lead to premature detachment, misalignment, reduced efficacy, and even safety hazards [17, 28].

Installing road markers necessitates a range of essential tools and materials, including the reflective road markers themselves (plastic, aluminum, or solar types), road marking adhesive (epoxy, butyl pads), a power drill with appropriate bits (if required), pavement cleaner/brushes, a tape measure/chalk line, and personal protective equipment (PPE) [28, 29].

Avoid installing on dirty or wet road surfaces, using substandard or expired adhesives, incorrect road marker spacing, and failing to control traffic during installation [17, 28]. Additionally, installation should be avoided during rain or extremely low temperatures, as these can affect the installation outcome [31].

The detailed installation steps and common errors outlined above remind us that the performance of road markers depends not only on their inherent quality but equally on the quality of their installation. This is a systemic process where pavement preparation, adhesive selection, and precise placement are interdependent. This means that even with an investment in high-quality road markers, their effectiveness and lifespan will be compromised if installation best practices are not followed. Therefore, training installation teams and strict adherence to guidelines are as important as the product selection itself. Furthermore, the specific considerations for asphalt versus concrete pavements, and for high temperature, low temperature, or rainy conditions, indicate that installation is not a one-size-fits-all process. Environmental factors dictate the specific choice of adhesive types and installation techniques. This highlights the importance of adaptability and expertise in road infrastructure projects. Optimal performance is achieved through a nuanced understanding of both the product and its operational environment.

Regular maintenance is crucial for ensuring the long-term stability, optimal reflective performance, and safety contribution of road markers [17, 33, 34]. Effective maintenance can extend the lifespan of road markers by 20-30% [33].

Beyond regular cleaning and inspection, selecting high-quality products, standardized installation, and establishing maintenance records are key. For high-traffic areas, upgrading to smart road markers with remote monitoring capabilities can provide real-time status and early warnings [33].

The emphasis on "regular cleaning," "periodic inspection," and "timely replacement" indicates a proactive maintenance strategy. The statistic that regular maintenance can extend lifespan by 20-30% [33] directly links proactive efforts to extended longevity, thereby yielding a better return on investment (ROI) and sustained safety. This suggests that the "cost-effectiveness" of non-powered markers isn't just in their initial purchase, but also in intelligent lifecycle management. Neglecting maintenance will significantly erode their long-term value.

Furthermore, despite the core topic being "non-powered" markers, the mention of "leveraging smart maintenance technologies" and "automated monitoring systems" [34], as well as "smart road markers with remote monitoring capabilities" [33], shows a broader trend. Even passive devices are being integrated into smart infrastructure ecosystems for better management. This hints at a future for road safety infrastructure where data and technology increasingly guide maintenance schedules and performance monitoring, even for traditionally analog components. This will lead to increased efficiency and ensure sustained levels of safety.

Road markers must adhere to stringent national and international standards to ensure consistent performance, reliability, and safety across different regions [35].

While some sources mention ISO 3758 and ASTM D4956 as relevant to road marker standards [35], further investigation reveals that ISO 3758 primarily pertains to textile care labeling [46, 47], and ASTM D4956 applies to retroreflective sheeting for traffic signs [35]. Although reflective quality is relevant to road markers, these standards do not directly address road markers themselves in the same way as EN 1463-1 and ASTM D4280. This distinction is crucial for ensuring informational accuracy.

The existence of detailed international standards such as EN 1463-1 and ASTM D4280 signifies a global effort towards consistent safety performance [11, 12, 35, 37, 38, 39, 40, 41, 42, 43, 44, 45, 48]. These standards not only assure quality but also facilitate international trade by providing common benchmarks. Compliance with these standards is more than just a regulatory requirement; it's a mark of quality and a commitment to road user safety, making it a key differentiator for suppliers and a crucial requirement for infrastructure projects.

Furthermore, the evolution of standards, such as the proposed phasing out of "Undetermined Performance" classes in EN 1463-1 [39] and specific physical testing in ASTM D4280 [11, 44, 45], indicates that standards are not static. They continually adapt to new research, material advancements, and the demand for higher performance thresholds. This drives manufacturers to innovate and improve product quality. This dynamic nature of standards means that product development in road safety is continuously pushed by stricter requirements, ultimately leading to safer and more durable solutions for end-users.

| Requirement Category | EN 1463-1 Standard | ASTM D4280 Standard |

|---|---|---|

| Retroreflectivity | Minimum 100 cd/lx/m² [35] | Coefficient of Luminous Intensity (RI) must meet specified values [11, 41, 44] |

| Durability/Lifespan | Reflective surface to last at least 5 years under normal traffic conditions [35]; "Undetermined Performance" classes being phased out to ensure road testing [39] | Long-life type markers [41, 42]; 6-month road test to determine cleanability and durability [41] |

| Compressive Strength | Not explicitly quantified, but classified (Type A for non-depressible, Type B for depressible) [37, 38] | Withstands 2727 kg (6000 lbs) load without fracture or significant deformation (3.3 mm) [11, 44, 45] |

| Flexural Strength | Not explicitly quantified, but classified (Type F markers have sufficient longitudinal strength) [11] | Withstands 909 kg (2000 lbs) load without fracture (for Type F markers) [11, 41, 45] |

| Lens Impact Strength | Not explicitly quantified | No more than two radial cracks, not exceeding 6.4 mm in length on lens surface [11, 44] |

| Dimensions | Not explicitly quantified, but classified (e.g., 3M™ RPM Series 290 classified as Type P3A) [40] | Height not exceeding 20.3 mm (0.80 inches), width not exceeding 130 mm (5.1 inches) [11, 12, 41, 44] |

| Bond Strength | Secured to the road surface by adhesive [37, 39] | Bond strength of flat-bottom markers not less than 3.4 MPa (500 psi) [41] |

| Resistance to Temperature Cycling | Not explicitly quantified | No cracking or delamination [11] |

The value of non-powered reflective road markers extends far beyond their direct safety benefits; they also play a significant role in environmental sustainability and economic efficiency.

Unlike traditional streetlights or active LED road signs, non-powered reflective road markers operate without electricity. They rely entirely on the principle of retroreflection, significantly reducing dependence on fossil fuel-generated electricity and thereby lowering carbon emissions [7]. This energy-free operation is particularly advantageous in rural or remote areas where power supply is limited or costly [7].

By eliminating the need for complex wiring, external power sources, or fuel-based lighting solutions, passive reflective pavement markers contribute to a reduced carbon footprint associated with road infrastructure. Their production and operation generate minimal greenhouse gas emissions compared to active lighting systems [7].

High-quality reflective road markers are designed to be robust and durable, often lasting for many years without frequent replacement [7]. Their extended lifespan minimizes material waste and reduces the frequency of manufacturing, transport, and disposal processes. Reduced maintenance needs also mean fewer emissions from maintenance vehicles and personnel [7].

Despite initial installation costs, the absence of ongoing electricity bills and reduced maintenance requirements make non-powered reflective road markers a highly cost-effective solution in the long run, especially when compared to installing and operating streetlights [3, 7]. Their durability further contributes to long-term savings by reducing replacement frequency [7, 16, 19].

Integrating these passive road safety solutions into smart infrastructure planning can help municipalities reduce energy costs while ensuring road safety, aligning with global efforts to build greener, more efficient urban road networks [7].

The environmental and economic benefits of non-powered road markers [3, 6, 7] are not immediately obvious, but their lack of electricity consumption, low carbon footprint, and reduced maintenance costs make them a vital component of sustainable infrastructure. This broadens the appeal and value proposition of non-powered markers, making them attractive not only to safety engineers but also to urban planners and policymakers concerned with environmental stewardship and long-term financial sustainability.

Furthermore, the statement that they "reduce the need for energy-intensive streetlights in certain areas" [7] indicates their complementary role, rather than replacement. This implies a strategic approach to energy management where passive markers can fill gaps or supplement illumination in areas where full streetlight installation is impractical or energy-intensive. This positions non-powered road markers as part of a diversified strategy for road illumination and safety, contributing to overall energy efficiency goals in transportation infrastructure.

Non-powered reflective road markers are an indispensable component of modern road safety, providing enhanced visibility, improved lane discipline, effective speed management, and clear hazard indication.

These passive devices demonstrate exceptional effectiveness in challenging conditions such as nighttime and adverse weather, proving to significantly reduce accidents. Beyond their core safety functions, non-powered reflective road markers also offer substantial environmental and economic advantages. They operate without electricity, significantly reducing energy consumption and carbon footprint, and their durability minimizes maintenance needs and waste generation. In the long run, these characteristics make them a highly cost-effective solution, supporting sustainable urban development and greener transportation networks.

By investing in high-quality, internationally compliant non-powered reflective road markers, we can not only enhance road safety but also pave the way for a more efficient and sustainable transportation future. These robust guardians of our roads, with their simple principle and profound impact, will continue to guide us safely forward.